Open Hours:8:30am-20:30pm

Whatsapp:+86 198-5901-3937

CNC Bridge Saw for Sale-Premium Stone Cutting Machine

CNC Bridge Saw for Sale-Premium Stone Cutting Machine

QSQJ-400/600/800

QSQJ-400/600/800

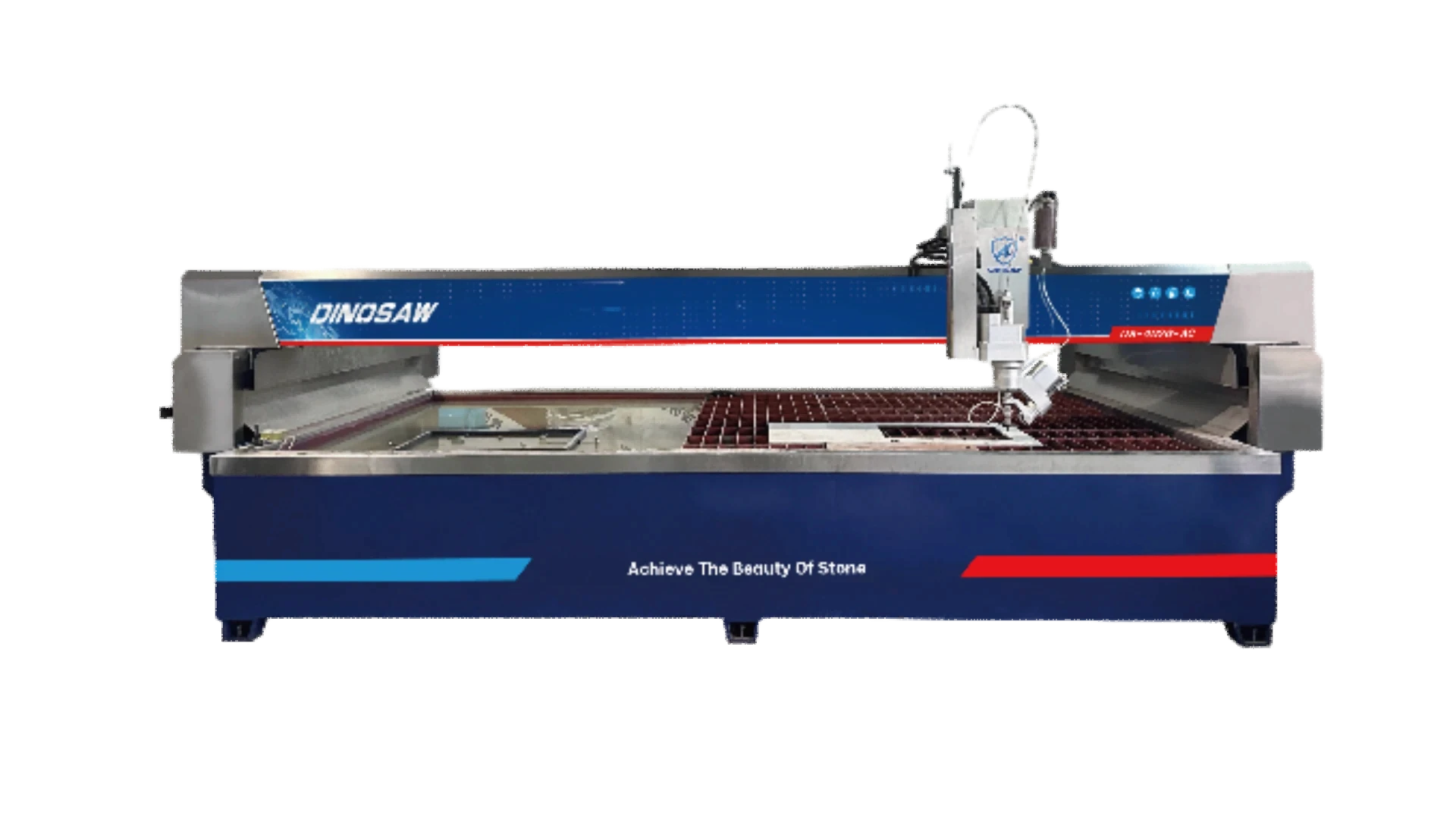

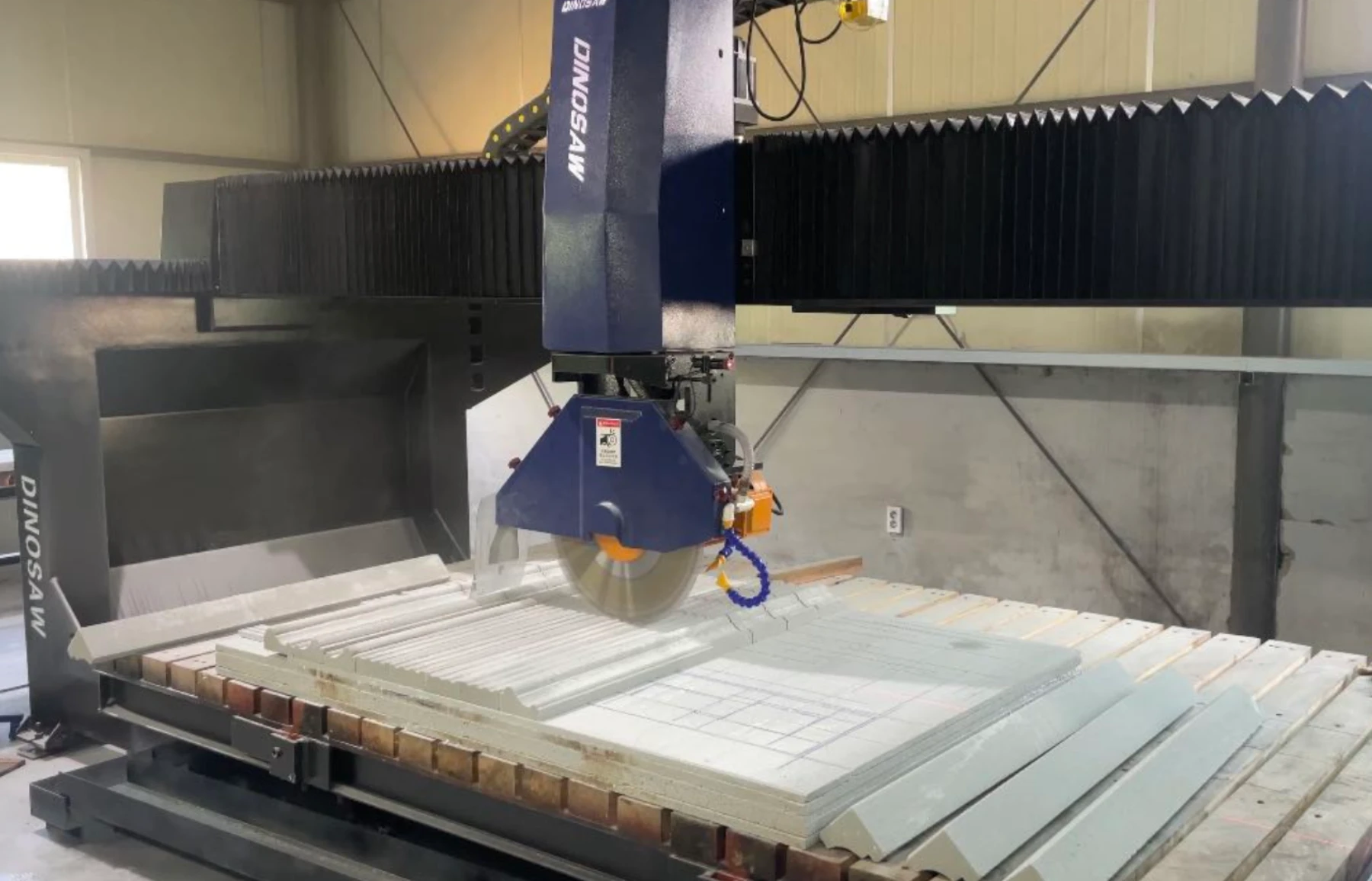

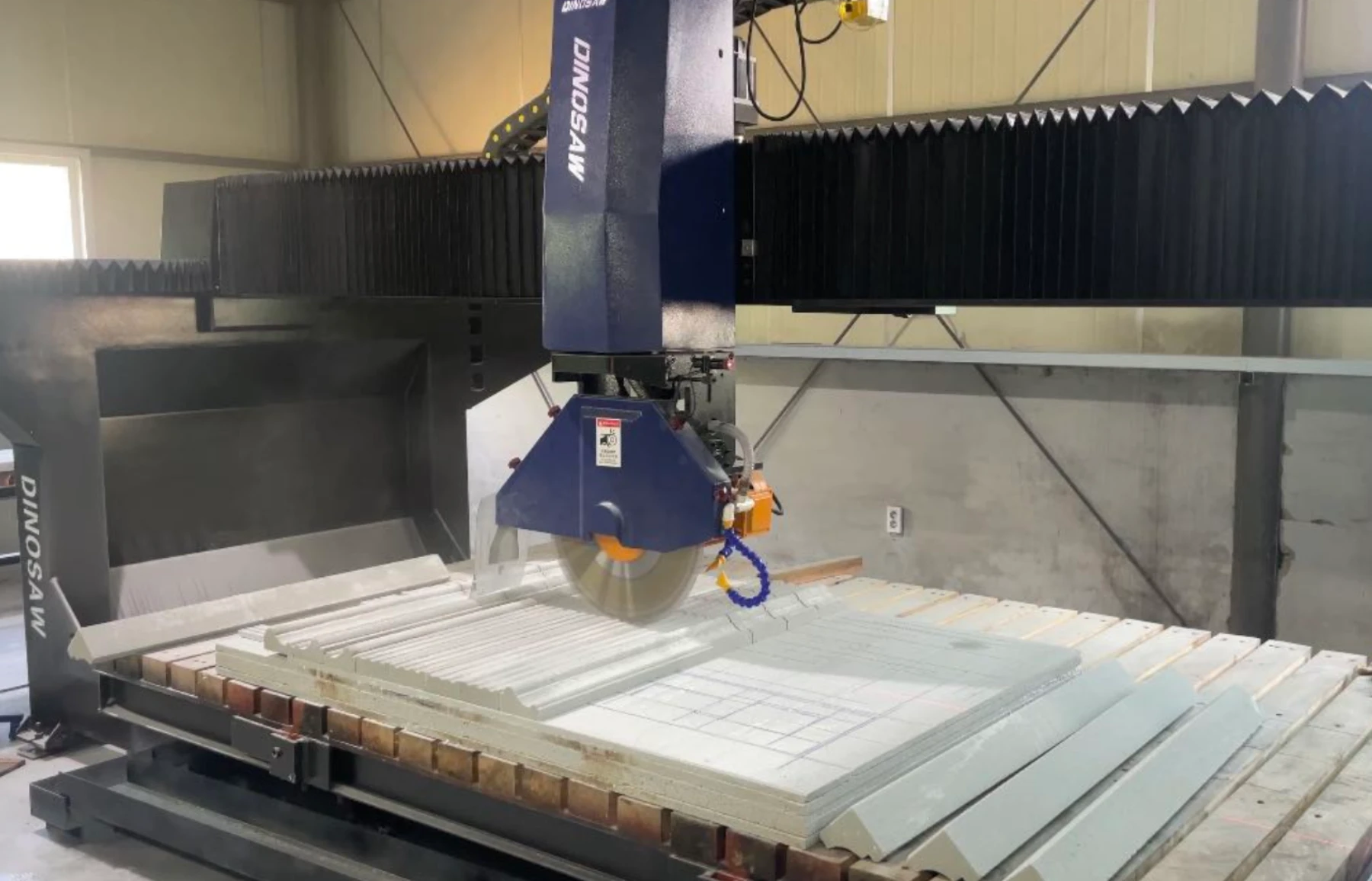

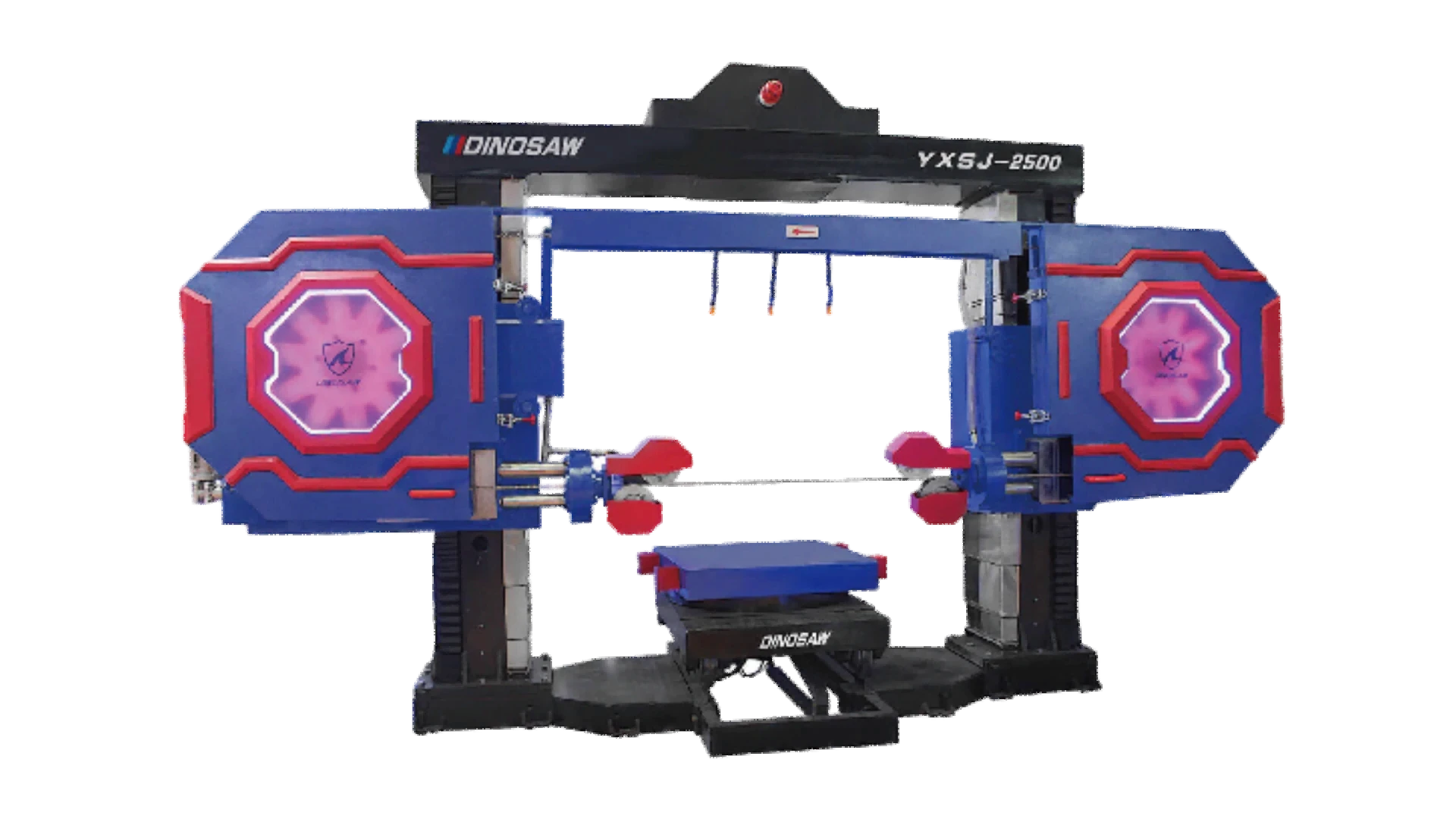

DINOSAW CNC Bridge Saw Machines are engineered specifically for stone fabricators, offering a range of 3-5 axis configurations. These machines deliver high-precision cutting for marble, granite, engineered stone, and ceramic tile, perfect for creating countertops, sinks, monuments, and more. Our machines feature heavy-duty cast iron bridge beams and precision guide rails, paired with globally recognized DDX control systems. Every production step undergoes strict quality control. Cutting precision reaches ±0.05mm with cutting speeds up to 25㎡/h for marble slabs. We customize the optimal bridge saw configuration for every stone fabricator's unique needs.

DINOSAW Bridge Saws are engineered specifically for stone fabricators, offering a range of 3-5 axis configurations. These machines deliver high-precision cutting for marble, granite, engineered stone, and ceramic tile, perfect for creating countertops, sinks, monuments, and more.

Our machines feature heavy-duty cast iron bridge beams and precision guide rails, paired with DDX control systems. Every production step undergoes strict quality control. Cutting precision reaches ±0.05mm with cutting speeds up to 25㎡/h for marble slabs. We customize the optimal bridge saw configuration for every stone fabricator's unique needs.

DINOSAW CNC Bridge Saw Machines are engineered specifically for stone fabricators, offering a range of 3-5 axis configurations. These machines deliver high-precision cutting for marble, granite, engineered stone, and ceramic tile, perfect for creating countertops, sinks, monuments, and more. Our machines feature heavy-duty cast iron bridge beams and precision guide rails, paired with globally recognized DDX control systems. Every production step undergoes strict quality control. Cutting precision reaches ±0.05mm with cutting speeds up to 25㎡/h for marble slabs. We customize the optimal bridge saw configuration for every stone fabricator's unique needs.

Share

Machine Details

Four Reasons Top Stone Fabricators Choose DINOSAW Bridge Saw

⚡Superior Cutting Speed

Cut marble at 25㎡/h with DINOSAW bridge saws—outperforming industry standards. Our Italian industrial motors deliver high-torque output through direct-drive design, minimizing transmission losses while efficiently cutting even the hardest stone materials.

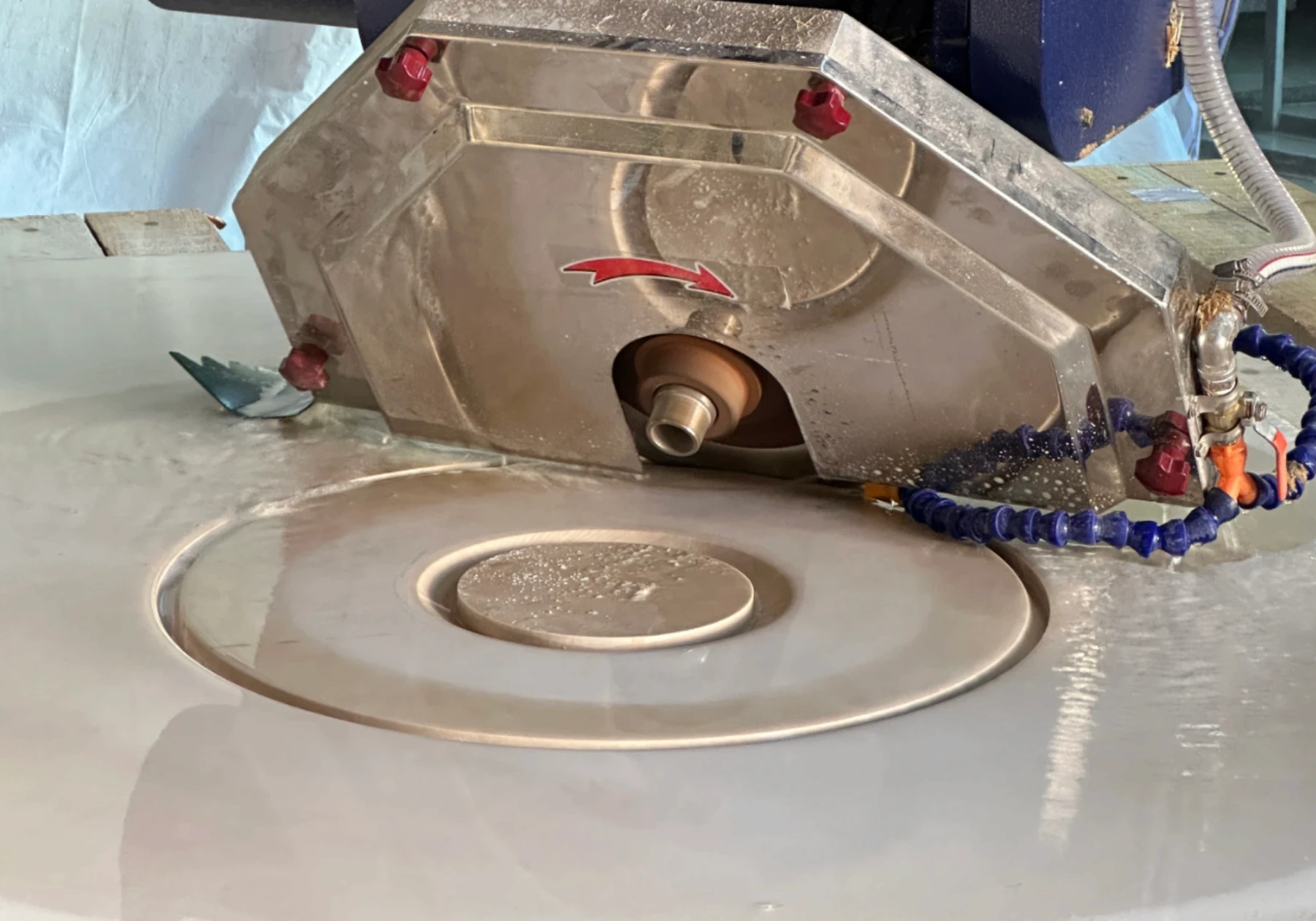

🎯Exceptional Precision

Achieve ±0.05mm cutting accuracy with our precision-engineered systems. Italian motors with balanced rotors and precision bearings deliver minimal runout, while DDX control systems automate measurement and processing—eliminating human error for consistent high-precision results.(via DDX EasySTONE)

💰Cost-Effective Operation

Save time and labor with automated systems that eliminate manual measurement and drawing. Our cast iron structure and rack-and-pinion transmission maintain stability during high-speed cutting, while accessible maintenance points reduce long-term operating costs.(via What is Cast Iron – Definition)

🔄Unmatched Versatility

Choose from multiple axis setups (3/4/4+1/5-axis) and machine structures (monoblock/split). Add accessories like milling tools, rotating worktables, and vacuum lifters. Customize voltage, dust collection, and noise reduction systems to match your production environment perfectly.

Bridge Saw Model Selection Guide: Understanding Different CNC Options

Selecting the wrong bridge saw model can lead to low work efficiency, increased material waste, or even requiring additional equipment investments. Understanding the core differences between bridge saw types will help you make the wisest choice for your production needs:

What is the Best Bridge Saw? Different CNC Bridge Saw Model Comparison

Parameter | 3-Axis CNC Bridge Saw | 4-Axis CNC Bridge Saw | 4+1-Axis CNC Bridge Saw | 5-Axis CNC Bridge Saw |

|---|---|---|---|---|

Main Applications | Standard slab cutting, simple countertops | Custom countertops, multi-angle cutting | Countertop fabrication, sink cutouts, edge finishing | Complex curved surface processing, high-end custom countertops |

Main Functions | Straight-line cutting, 45° angle cutting | Multi-angle cutting, curved-line cutting | Multi-angle cutting, curved-line cutting, precision drilling, edge finishing | All-angle cutting, complex surface processing, precision drilling, edge finishing |

Axis Functionality | X/Y/Z linear movement | X/Y/Z + C-axis rotation (0-360°) | X/Y/Z + C-axis rotation + milling tool | X/Y/Z + C-axis (0-360°) + A-axis (0-90°) |

Max Processing Dimensions | 3000×2000×680mm | 3000×2000×280mm | 3000×2000×180mm | 3000×2000×180mm |

Max Blade Diameter | 1600mm | 800mm | 600mm | 600mm |

Control System | PLC Control | PLC/CNC Control | CNC Control | DDX System |

Machine Structure | Monoblock/Split optional | Monoblock (head rotation)/Split (table rotation) | Monoblock (head rotation)/Split (table rotation) | Monoblock (head rotation) |

Not Sure Which to Choose?

If you're still uncertain which bridge saw best suits your production needs, contact DINOSAW's professional advisory team. We'll provide the most appropriate equipment recommendations and customized solutions based on your factory size, processing material types, product categories, and budget.

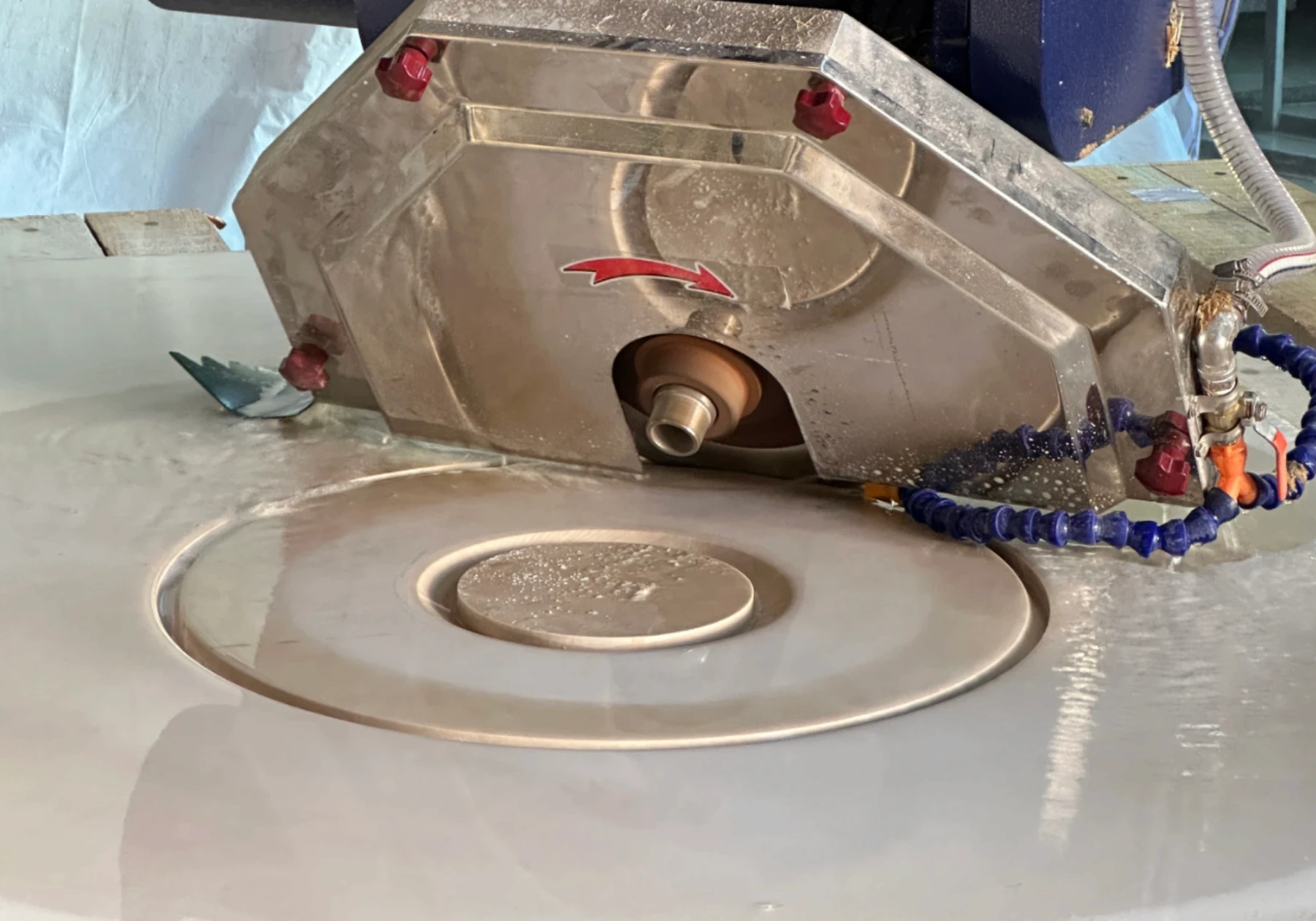

What Does a Bridge Saw Do? CNC Bridge Saw Operating Principles

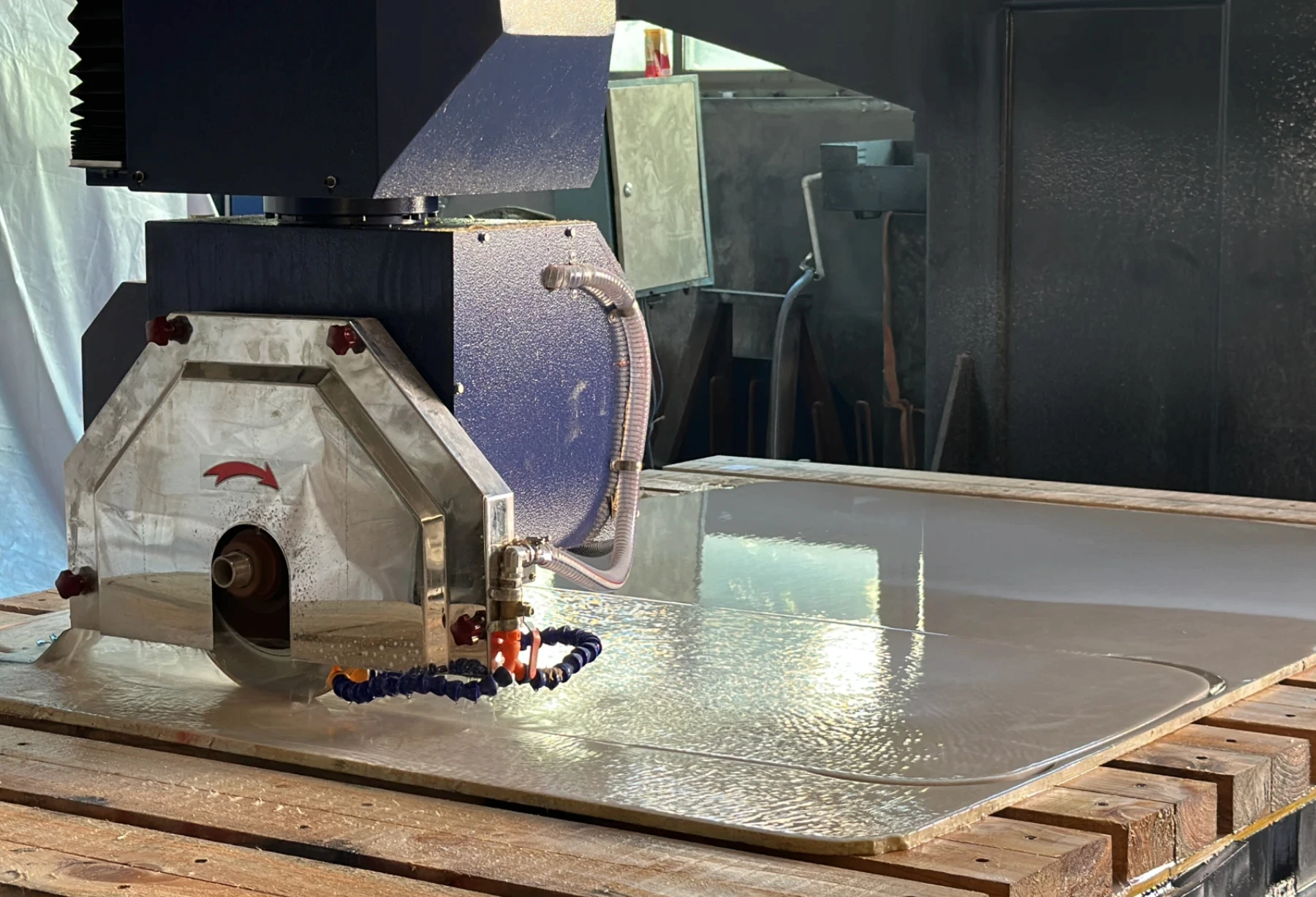

In stone processing, a Bridge Saw is not just a simple cutting device. It achieves precise fabrication through high-precision control systems working in coordination with diamond blades. Choose the right configuration and cut marble at 25㎡/h. More axes = more capabilities:

🔸 3-AXIS Bridge Saw (IDEAL FOR STANDARD SLABS)

X/Y/Z linear movement • Straight-line cutting and 45° angle cutting • Simple operation with low training requirements

🔸 4-AXIS Bridge Saw (IDEAL FOR CUSTOM COUNTERTOPS)

Adds 360° rotation capability, enabling: • Multi-angle cutting without manual repositioning • Simple curved-line processing • 40% faster countertop fabrication workflow

🔸 4+1-AXIS Bridge Saw (IDEAL FOR COMPLETE FABRICATION)

All 4-axis capabilities plus auxiliary milling tool • Switch between cutting and drilling without changing machines • Precise sink cutouts and edge finishing • Reduce workflow from 3 machines to 1

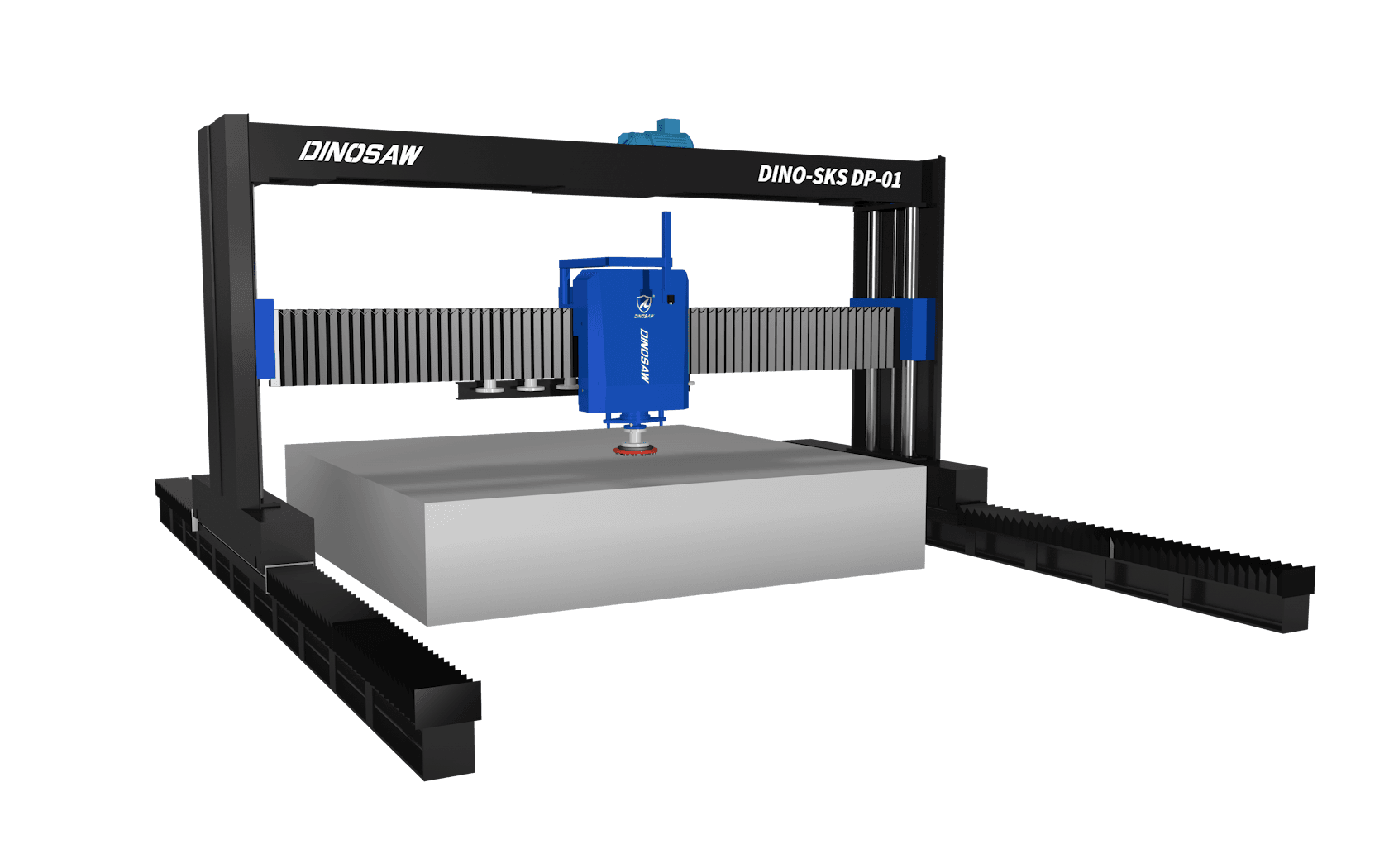

🔸 5-AXIS Bridge Saw (IDEAL FOR COMPLEX PROJECTS)

Full 3D processing capability with blade tilt 0-90° • Process any angle in three-dimensional space • Complex curved surface cutting and edge profiling • Perfect for high-end architectural elements

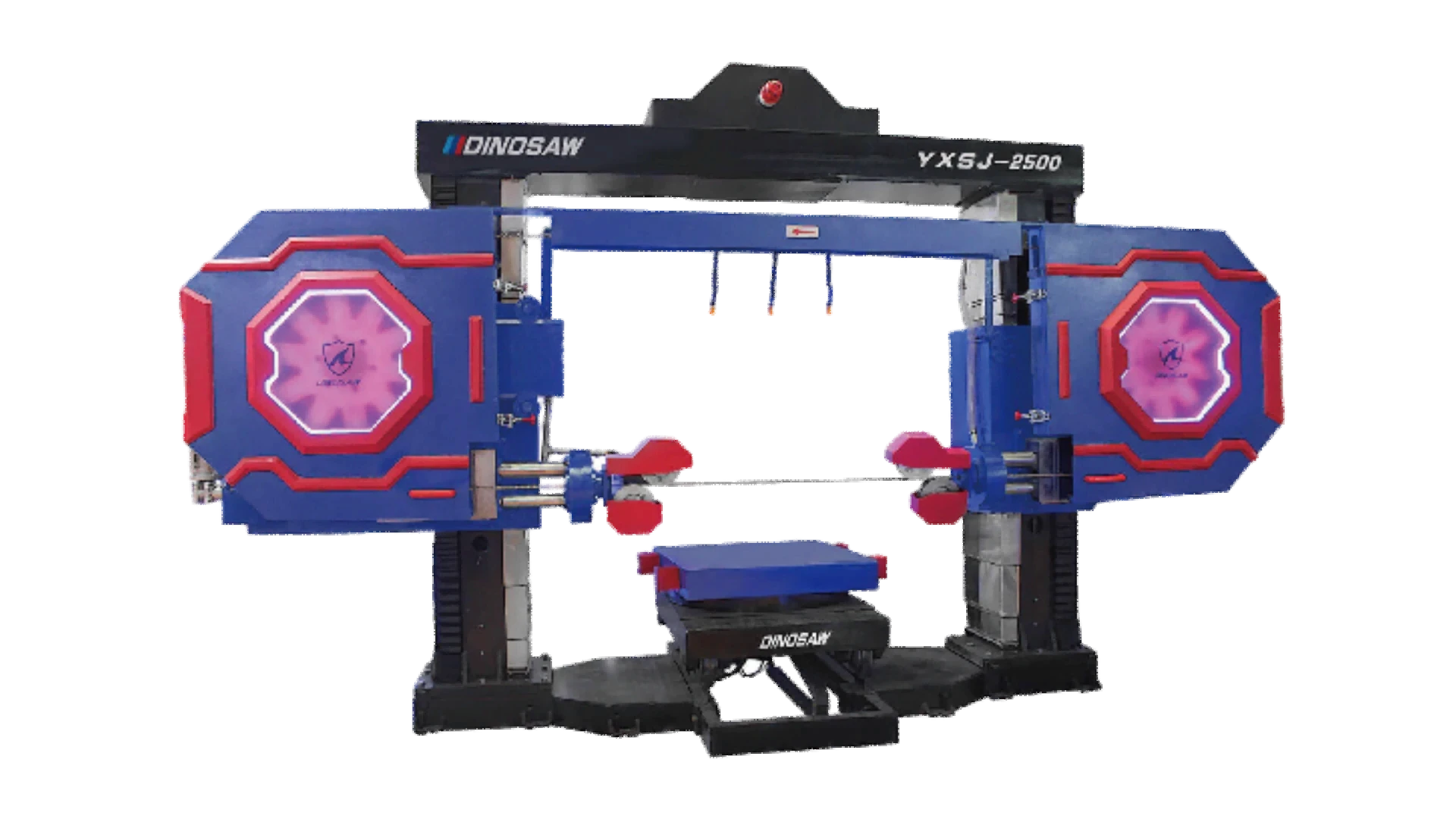

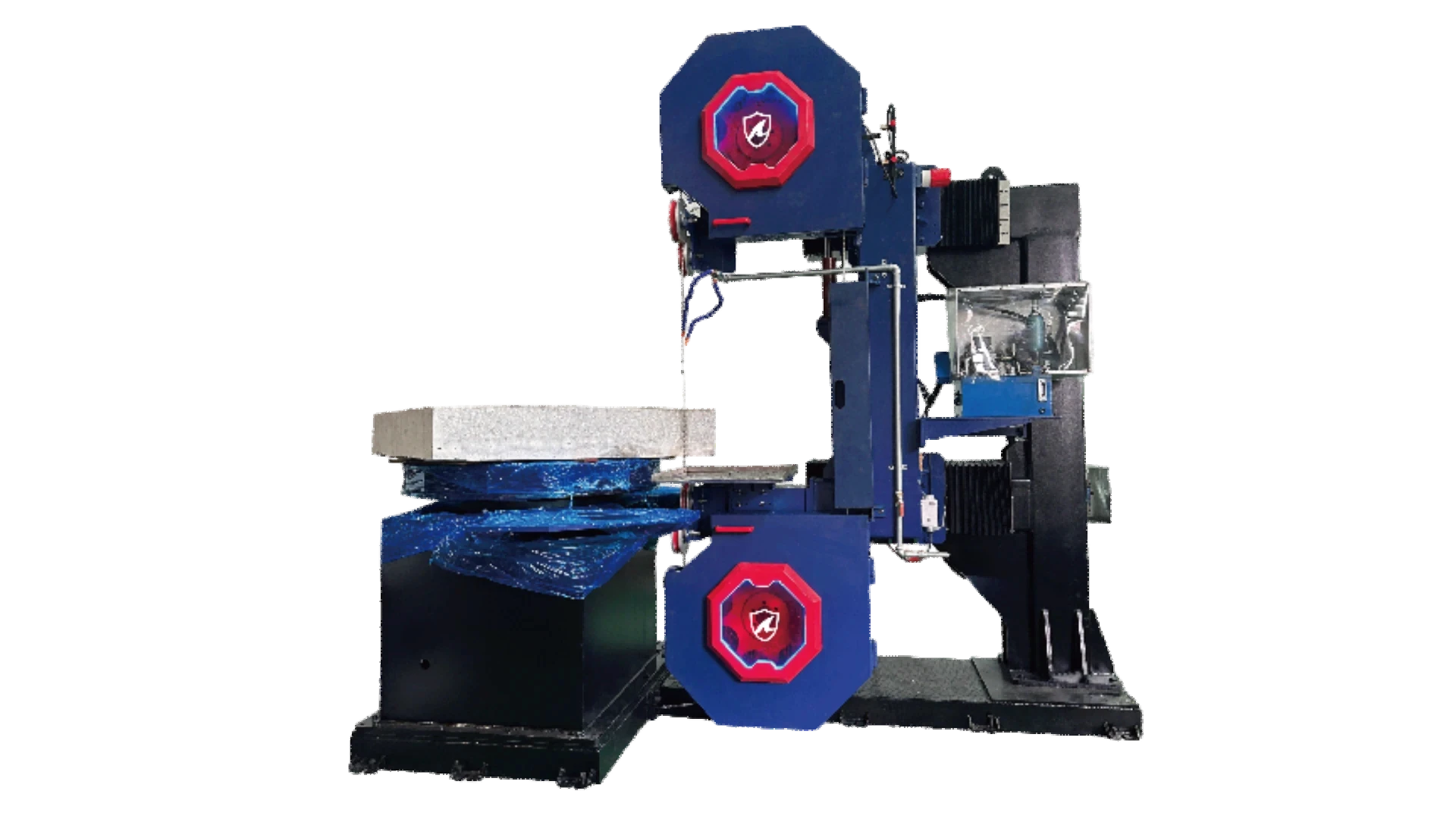

Monoblock Bridge Saw vs. Split Structure Comparison

Beyond axis configuration, structural type directly impacts processing capabilities and installation convenience. DINOSAW offers two main structural types:

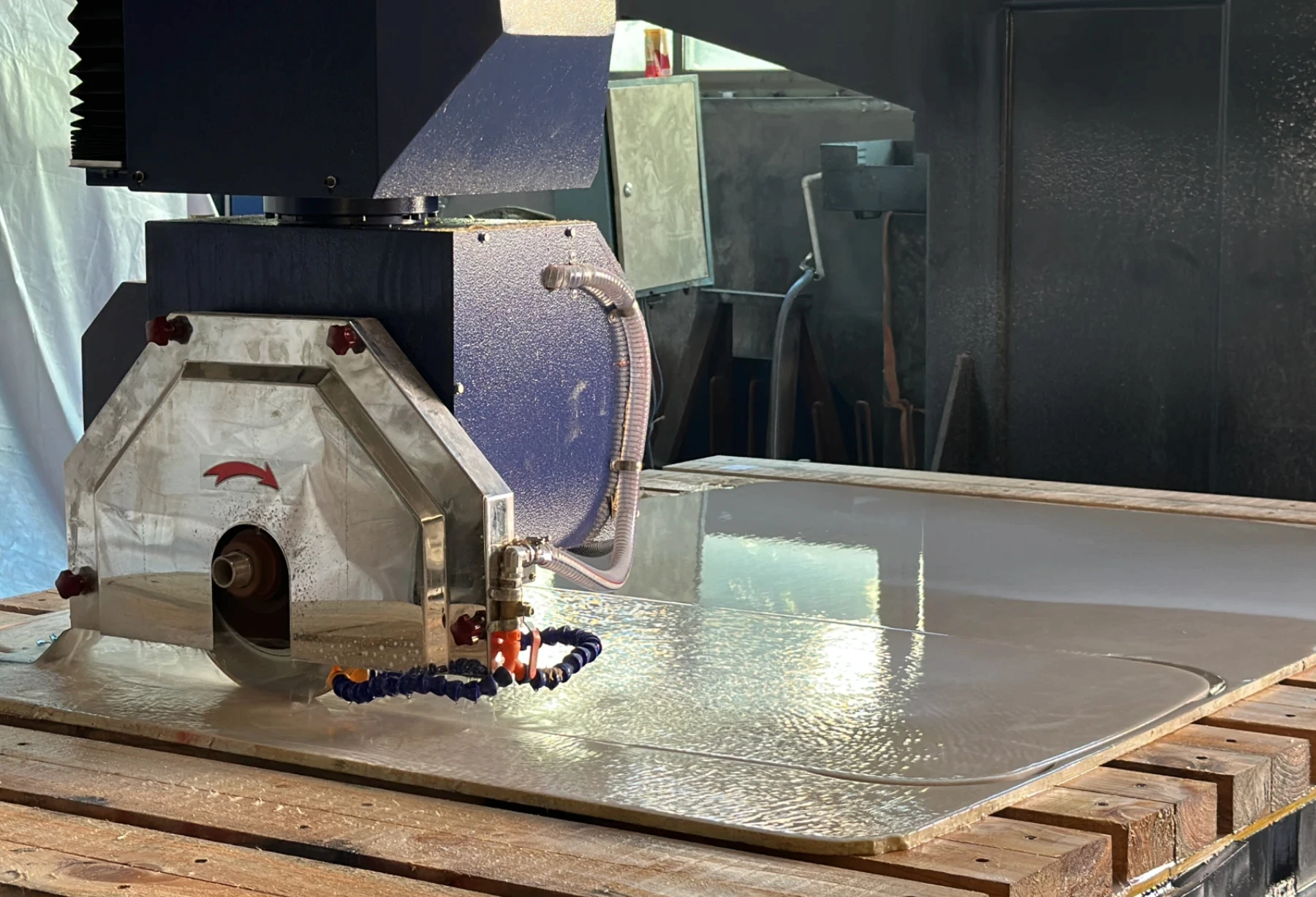

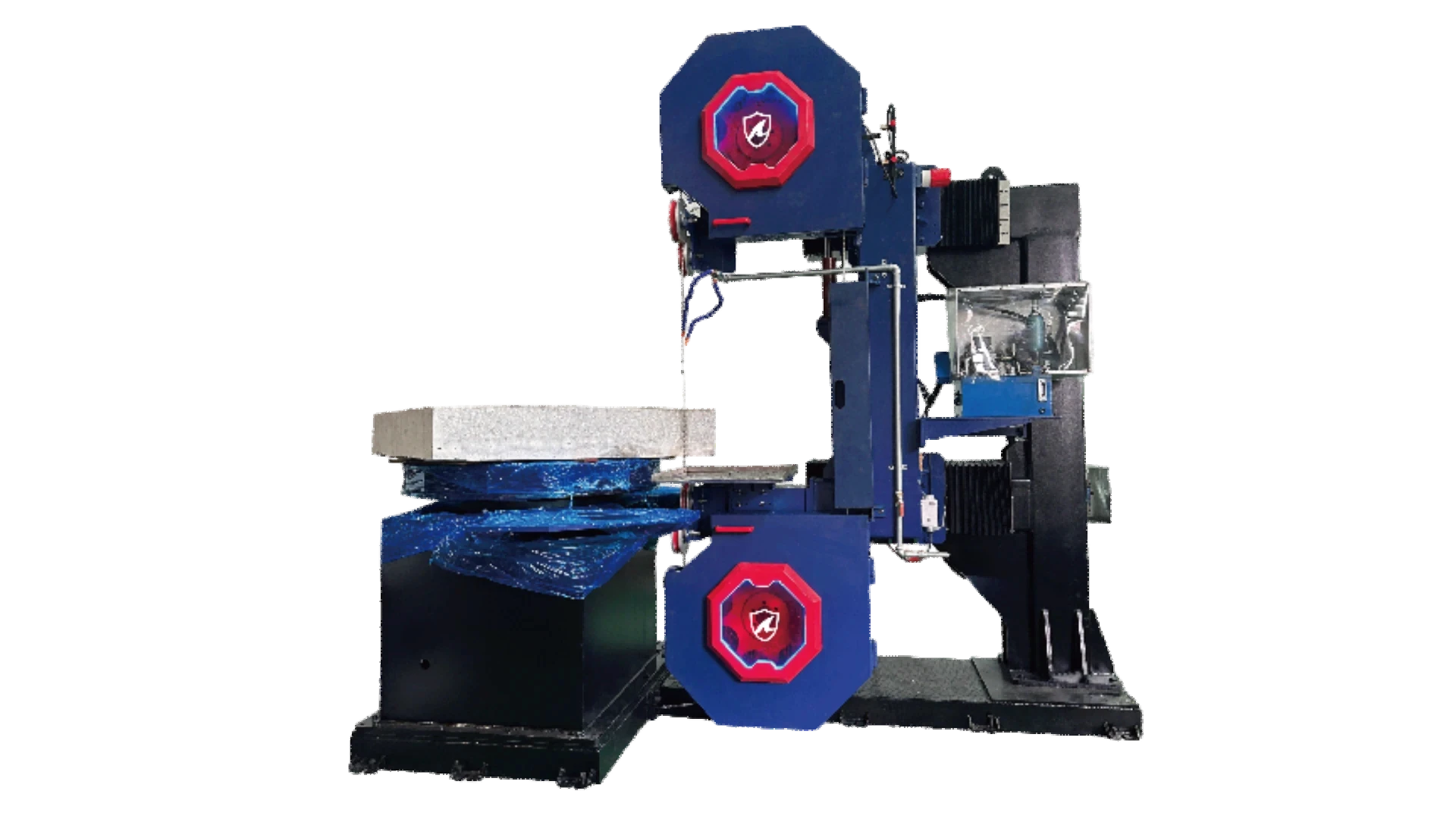

✅Monoblock Structure: The frame and worktable are integrated into a single unit, featuring:

Space-saving installation, perfect for stone fabrication workshops with limited floor area

One-piece design for easier transport, installation, and relocation without complex foundation workIn 4-axis and higher configurations, only head/blade rotation is possible since the worktable is integrated with the frame

Suitable for small to medium fabrication shops and production environments requiring equipment mobility

✅Split Structure: The main equipment body is separate from the base, with different base options:

Concrete base: Offers maximum stability, ideal for permanent fixed-position use

Steel structure base: Balances stability with some mobility convenience

When paired with a heavy-duty base, provides higher processing precision, suitable for large stone pieces and high-precision requirementsSplit design allows worktable rotation, enabling more flexible processing angle adjustments

Different scenarios demand different solutions. For high-volume production of identical products, a split machine with a heavy-duty base provides better stability. For frequent product line changes or limited space, a monoblock structure offers greater flexibility. DINOSAW's professional team can recommend the most suitable structure based on your specific working environment and processing needs.

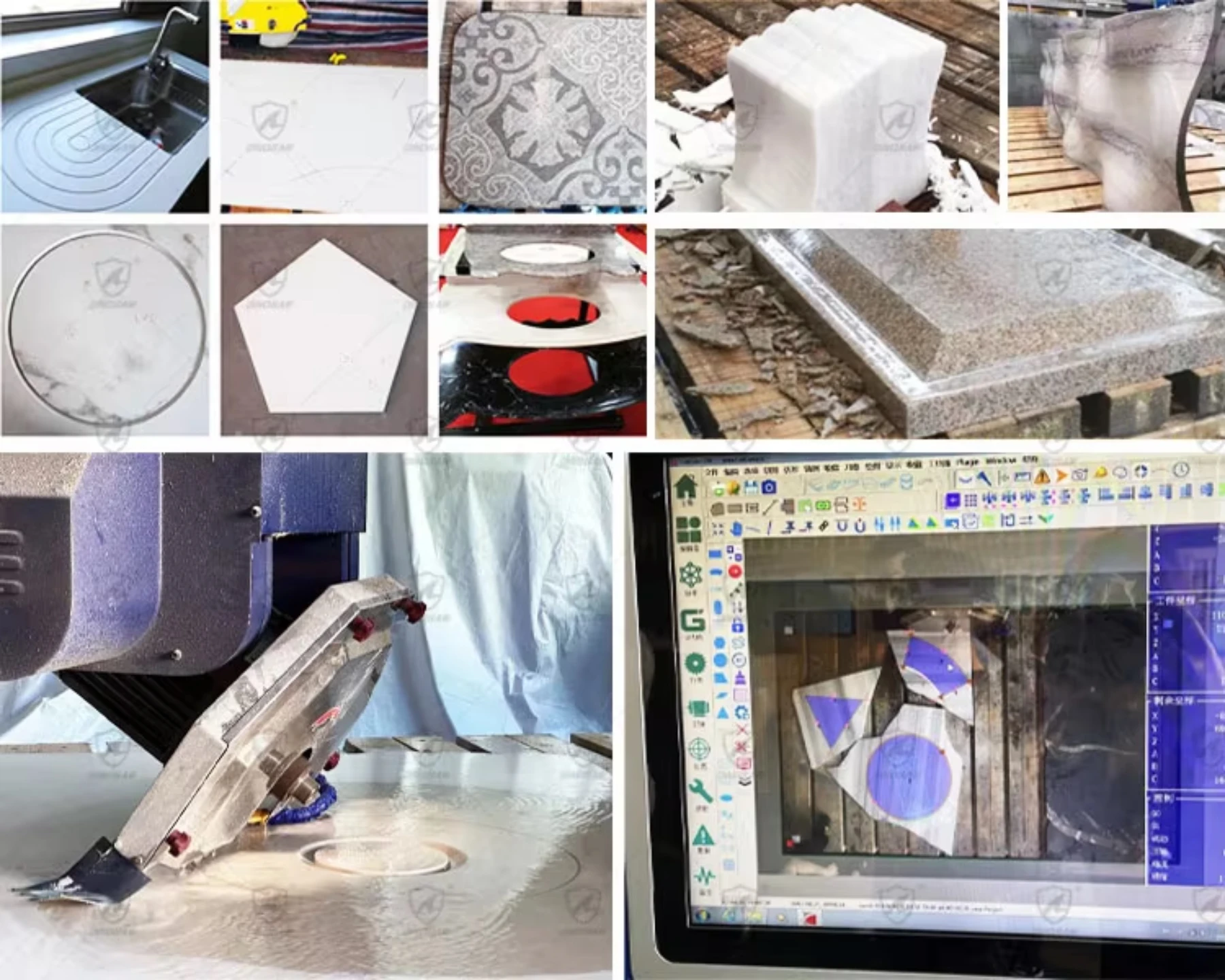

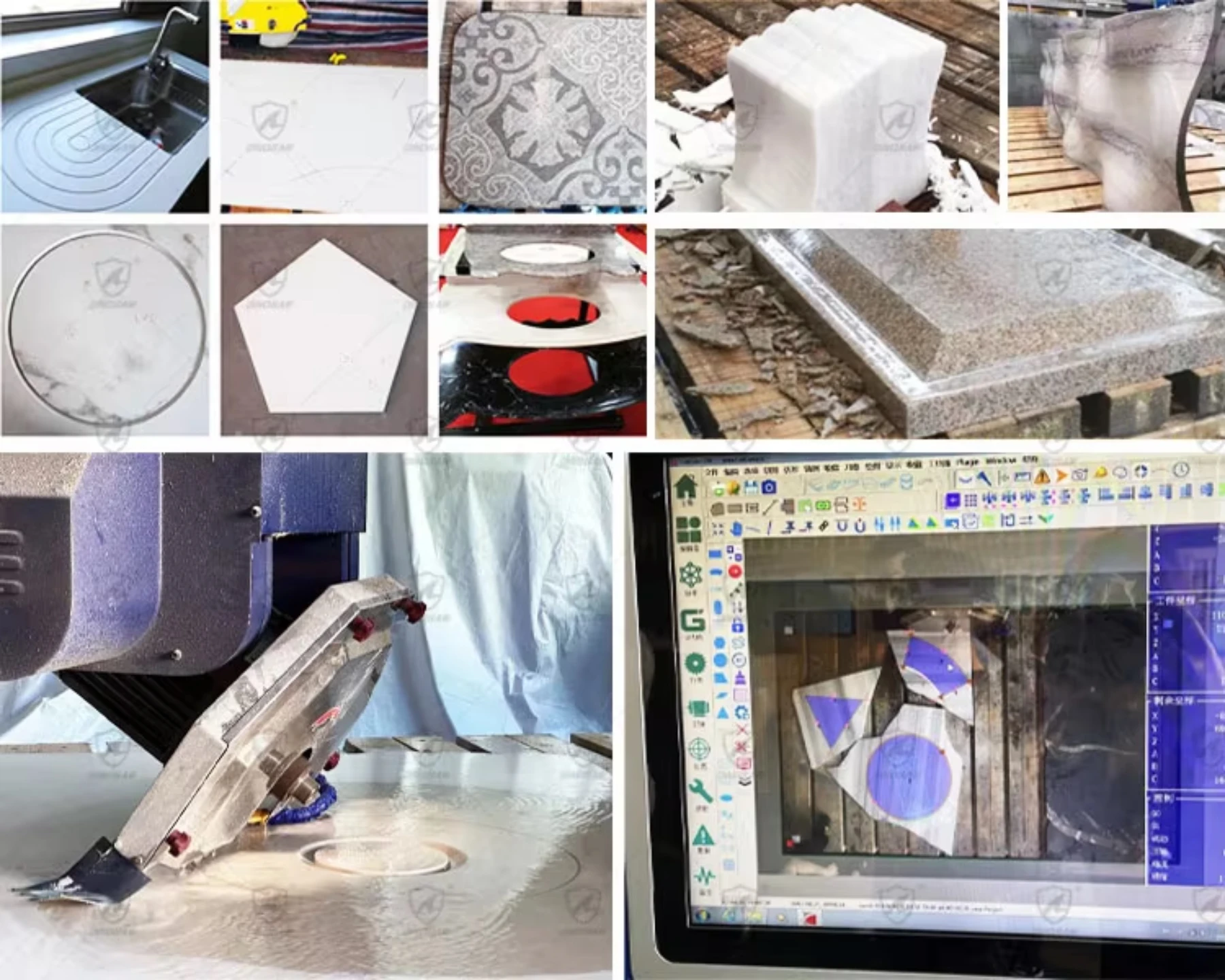

Bridge Saw Machine Application Cases

It's difficult to fully appreciate equipment value from specifications alone. Here are breakthrough results achieved by actual customers using DINOSAW bridge saws, which might inspire your decision:

High-Efficiency Slab Cutting

An Italian marble manufacturer previously used traditional equipment to process Carrara White marble, achieving only 60 square meters daily with cutting errors up to ±2mm.

After upgrading to a DINOSAW granite bridge saw, they achieved marble slab cutting efficiency of 25㎡/h with cutting precision within ±0.1mm, improving material utilization by 18%. The equipment investment paid for itself within 8 months.

Custom Kitchen & Bath Countertop Production

An American countertop fabricator faced intense market competition. After adopting DINOSAW's 4+1 axis CNC stone cutting equipment, a single granite cutter machine simultaneously handled cutting, drilling, and edge finishing.

This simplified a workflow that previously required 3 machines, allowing 2 operators to efficiently produce complex kitchen countertops and vanity tops. Production efficiency increased by 40%, while delivering more precise sink cutouts and edge treatments.

Architectural Decorative Component Processing

A Middle Eastern luxury project contractor needed to process high-end stone decorative elements in travertine and onyx. After implementing DINOSAW's 5-axis bridge saw, they achieved complex curved surface processing and precision drilling, providing perfect solutions for claddings and decorative elements. The equipment reduced production cycle time from 15 days to 3 days, increasing project profit margins from 20% to over 60%.

Engineered Stone Precision Processing

A European fabrication shop frequently encountered cutting quality issues when processing porcelain slabs and sintered stone, with a defect rate reaching 30%. After implementing a DINOSAW 4-axis bridge saw optimized for hard materials, the equipment intelligently adjusted cutting parameters to maintain optimal working conditions. The defect rate dropped below 5%, saving over €8,000 monthly in material and labor costs.

Reliable Bridge Saw Manufacturer:DINOSAW

When selecting a bridge saw manufacturer, both product quality and long-term service capabilities are crucial considerations. DINOSAW provides unique advantages that directly impact your bottom line:

🏭Factory-Direct Manufacturing

Unlike equipment distributors, DINOSAW is a specialized stone machinery manufacturer with dedicated engineering facilities. This factory-direct approach eliminates middleman markups, saving customers 15-30% on comparable machines. Our manufacturing expertise enables truly customized solutions rather than minor modifications to standard models.

🌐Global Service Network

With service points in 60+ countries and 700+ installations worldwide, DINOSAW provides comprehensive support regardless of location. Our technical centers in Italy, the United States, and Uzbekistan ensure rapid response through both local technicians and remote diagnostics systems.

Our R&D team continuously refines designs based on real-world feedback from diverse production environments. This ensures DINOSAW bridge saws meet evolving industry requirements while maintaining the reliability that has established us as China's leading manufacturer.

Frequently Asked Questions

What is a Bridge Saw? How does it differ from ordinary stone cutting machines?

A Bridge Saw is core equipment in modern stone fabrication, providing exceptional stability through its unique bridge structure. Unlike ordinary cutting equipment, CNC Bridge Saws process larger slabs (up to 3200×2000mm), offer multi-angle precision cutting (±0.05mm accuracy), and handle complex designs automatically. Essential for shops aiming to improve efficiency, reduce waste, and expand product offerings.

What materials can DINOSAW Bridge Saws cut?

DINOSAW Bridge Saws can process a wide range of finished stone products including dimensional stone slabs, tombstones, wall cladding, feature walls, sinks, countertops, vanity tops, floor tiles, stair treads, monuments, and more. Our machines are engineered to handle marble, granite, engineered stone, and ceramic materials with exceptional precision and efficiency.

How do I choose the right bridge saw model for my stone fabrication shop?

Choosing the right bridge saw is like finding the perfect partner for your shop—it should match your production needs perfectly rather than forcing you to adapt to it. These key factors will help you make an informed decision:

Material types: Different material hardness and characteristics require different cutting parameters

Product types: Standard slab cutting, countertop fabrication, or complex engraving require different axis configurations

Production scale: High-volume production versus custom fabrication have different efficiency and flexibility requirements

Budget considerations: Higher-end CNC equipment costs more but offers increased functionality and automation

Every fabrication shop is unique. DINOSAW's expert team has helped hundreds of stone fabricators select the most suitable equipment. Contact us for personalized recommendations to avoid long-term losses from improper selection.

How does DINOSAW handle bridge saw installation and operator training?

We understand that advanced equipment only delivers value when properly used. DINOSAW provides comprehensive "turnkey" service:

Professional technicians perform on-site installation and commissioning after equipment delivery

2-3 days of operational training covering basic operation, daily maintenance, and troubleshooting

Multilingual operation manuals, video tutorials, and technical documentation

Remote support systems for online diagnostics and software issue resolution

Transform Your Stone Workshop with Premium CNC Saw Machine - Elevate Precision & Productivity

Every DINOSAW bridge saw for sale is designed to enhance your competitive advantage. We don't just provide stone CNC machines—we transfer successful experience, helping you achieve improved production efficiency, reduced waste rates, and product innovation.

Custom Solutions: Analyze your actual needs and budget to avoid overinvestment or insufficient functionality

Complete Support: Beyond selling products, we become your long-term technical advisor and support system

Related Products: Stone Block Cutting Machine

Machine Details

Four Reasons Top Stone Fabricators Choose DINOSAW Bridge Saw

⚡Superior Cutting Speed

Cut marble at 25㎡/h with DINOSAW bridge saws—outperforming industry standards. Our Italian industrial motors deliver high-torque output through direct-drive design, minimizing transmission losses while efficiently cutting even the hardest stone materials.

🎯Exceptional Precision

Achieve ±0.05mm cutting accuracy with our precision-engineered systems. Italian motors with balanced rotors and precision bearings deliver minimal runout, while DDX control systems automate measurement and processing—eliminating human error for consistent high-precision results.(via DDX EasySTONE)

💰Cost-Effective Operation

Save time and labor with automated systems that eliminate manual measurement and drawing. Our cast iron structure and rack-and-pinion transmission maintain stability during high-speed cutting, while accessible maintenance points reduce long-term operating costs.(via What is Cast Iron – Definition)

🔄Unmatched Versatility

Choose from multiple axis setups (3/4/4+1/5-axis) and machine structures (monoblock/split). Add accessories like milling tools, rotating worktables, and vacuum lifters. Customize voltage, dust collection, and noise reduction systems to match your production environment perfectly.

Bridge Saw Model Selection Guide: Understanding Different CNC Options

Selecting the wrong bridge saw model can lead to low work efficiency, increased material waste, or even requiring additional equipment investments. Understanding the core differences between bridge saw types will help you make the wisest choice for your production needs:

What is the Best Bridge Saw? Different CNC Bridge Saw Model Comparison

Parameter | 3-Axis CNC Bridge Saw | 4-Axis CNC Bridge Saw | 4+1-Axis CNC Bridge Saw | 5-Axis CNC Bridge Saw |

|---|---|---|---|---|

Main Applications | Standard slab cutting, simple countertops | Custom countertops, multi-angle cutting | Countertop fabrication, sink cutouts, edge finishing | Complex curved surface processing, high-end custom countertops |

Main Functions | Straight-line cutting, 45° angle cutting | Multi-angle cutting, curved-line cutting | Multi-angle cutting, curved-line cutting, precision drilling, edge finishing | All-angle cutting, complex surface processing, precision drilling, edge finishing |

Axis Functionality | X/Y/Z linear movement | X/Y/Z + C-axis rotation (0-360°) | X/Y/Z + C-axis rotation + milling tool | X/Y/Z + C-axis (0-360°) + A-axis (0-90°) |

Max Processing Dimensions | 3000×2000×680mm | 3000×2000×280mm | 3000×2000×180mm | 3000×2000×180mm |

Max Blade Diameter | 1600mm | 800mm | 600mm | 600mm |

Control System | PLC Control | PLC/CNC Control | CNC Control | DDX System |

Machine Structure | Monoblock/Split optional | Monoblock (head rotation)/Split (table rotation) | Monoblock (head rotation)/Split (table rotation) | Monoblock (head rotation) |

Not Sure Which to Choose?

If you're still uncertain which bridge saw best suits your production needs, contact DINOSAW's professional advisory team. We'll provide the most appropriate equipment recommendations and customized solutions based on your factory size, processing material types, product categories, and budget.

What Does a Bridge Saw Do? CNC Bridge Saw Operating Principles

In stone processing, a Bridge Saw is not just a simple cutting device. It achieves precise fabrication through high-precision control systems working in coordination with diamond blades. Choose the right configuration and cut marble at 25㎡/h. More axes = more capabilities:

🔸 3-AXIS Bridge Saw (IDEAL FOR STANDARD SLABS)

X/Y/Z linear movement • Straight-line cutting and 45° angle cutting • Simple operation with low training requirements

🔸 4-AXIS Bridge Saw (IDEAL FOR CUSTOM COUNTERTOPS)

Adds 360° rotation capability, enabling: • Multi-angle cutting without manual repositioning • Simple curved-line processing • 40% faster countertop fabrication workflow

🔸 4+1-AXIS Bridge Saw (IDEAL FOR COMPLETE FABRICATION)

All 4-axis capabilities plus auxiliary milling tool • Switch between cutting and drilling without changing machines • Precise sink cutouts and edge finishing • Reduce workflow from 3 machines to 1

🔸 5-AXIS Bridge Saw (IDEAL FOR COMPLEX PROJECTS)

Full 3D processing capability with blade tilt 0-90° • Process any angle in three-dimensional space • Complex curved surface cutting and edge profiling • Perfect for high-end architectural elements

Monoblock Bridge Saw vs. Split Structure Comparison

Beyond axis configuration, structural type directly impacts processing capabilities and installation convenience. DINOSAW offers two main structural types:

✅Monoblock Structure: The frame and worktable are integrated into a single unit, featuring:

Space-saving installation, perfect for stone fabrication workshops with limited floor area

One-piece design for easier transport, installation, and relocation without complex foundation workIn 4-axis and higher configurations, only head/blade rotation is possible since the worktable is integrated with the frame

Suitable for small to medium fabrication shops and production environments requiring equipment mobility

✅Split Structure: The main equipment body is separate from the base, with different base options:

Concrete base: Offers maximum stability, ideal for permanent fixed-position use

Steel structure base: Balances stability with some mobility convenience

When paired with a heavy-duty base, provides higher processing precision, suitable for large stone pieces and high-precision requirementsSplit design allows worktable rotation, enabling more flexible processing angle adjustments

Different scenarios demand different solutions. For high-volume production of identical products, a split machine with a heavy-duty base provides better stability. For frequent product line changes or limited space, a monoblock structure offers greater flexibility. DINOSAW's professional team can recommend the most suitable structure based on your specific working environment and processing needs.

Bridge Saw Machine Application Cases

It's difficult to fully appreciate equipment value from specifications alone. Here are breakthrough results achieved by actual customers using DINOSAW bridge saws, which might inspire your decision:

High-Efficiency Slab Cutting

An Italian marble manufacturer previously used traditional equipment to process Carrara White marble, achieving only 60 square meters daily with cutting errors up to ±2mm.

After upgrading to a DINOSAW granite bridge saw, they achieved marble slab cutting efficiency of 25㎡/h with cutting precision within ±0.1mm, improving material utilization by 18%. The equipment investment paid for itself within 8 months.

Custom Kitchen & Bath Countertop Production

An American countertop fabricator faced intense market competition. After adopting DINOSAW's 4+1 axis CNC stone cutting equipment, a single granite cutter machine simultaneously handled cutting, drilling, and edge finishing.

This simplified a workflow that previously required 3 machines, allowing 2 operators to efficiently produce complex kitchen countertops and vanity tops. Production efficiency increased by 40%, while delivering more precise sink cutouts and edge treatments.

Architectural Decorative Component Processing

A Middle Eastern luxury project contractor needed to process high-end stone decorative elements in travertine and onyx. After implementing DINOSAW's 5-axis bridge saw, they achieved complex curved surface processing and precision drilling, providing perfect solutions for claddings and decorative elements. The equipment reduced production cycle time from 15 days to 3 days, increasing project profit margins from 20% to over 60%.

Engineered Stone Precision Processing

A European fabrication shop frequently encountered cutting quality issues when processing porcelain slabs and sintered stone, with a defect rate reaching 30%. After implementing a DINOSAW 4-axis bridge saw optimized for hard materials, the equipment intelligently adjusted cutting parameters to maintain optimal working conditions. The defect rate dropped below 5%, saving over €8,000 monthly in material and labor costs.

Reliable Bridge Saw Manufacturer:DINOSAW

When selecting a bridge saw manufacturer, both product quality and long-term service capabilities are crucial considerations. DINOSAW provides unique advantages that directly impact your bottom line:

🏭Factory-Direct Manufacturing

Unlike equipment distributors, DINOSAW is a specialized stone machinery manufacturer with dedicated engineering facilities. This factory-direct approach eliminates middleman markups, saving customers 15-30% on comparable machines. Our manufacturing expertise enables truly customized solutions rather than minor modifications to standard models.

🌐Global Service Network

With service points in 60+ countries and 700+ installations worldwide, DINOSAW provides comprehensive support regardless of location. Our technical centers in Italy, the United States, and Uzbekistan ensure rapid response through both local technicians and remote diagnostics systems.

Our R&D team continuously refines designs based on real-world feedback from diverse production environments. This ensures DINOSAW bridge saws meet evolving industry requirements while maintaining the reliability that has established us as China's leading manufacturer.

Frequently Asked Questions

What is a Bridge Saw? How does it differ from ordinary stone cutting machines?

A Bridge Saw is core equipment in modern stone fabrication, providing exceptional stability through its unique bridge structure. Unlike ordinary cutting equipment, CNC Bridge Saws process larger slabs (up to 3200×2000mm), offer multi-angle precision cutting (±0.05mm accuracy), and handle complex designs automatically. Essential for shops aiming to improve efficiency, reduce waste, and expand product offerings.

What materials can DINOSAW Bridge Saws cut?

DINOSAW Bridge Saws can process a wide range of finished stone products including dimensional stone slabs, tombstones, wall cladding, feature walls, sinks, countertops, vanity tops, floor tiles, stair treads, monuments, and more. Our machines are engineered to handle marble, granite, engineered stone, and ceramic materials with exceptional precision and efficiency.

How do I choose the right bridge saw model for my stone fabrication shop?

Choosing the right bridge saw is like finding the perfect partner for your shop—it should match your production needs perfectly rather than forcing you to adapt to it. These key factors will help you make an informed decision:

Material types: Different material hardness and characteristics require different cutting parameters

Product types: Standard slab cutting, countertop fabrication, or complex engraving require different axis configurations

Production scale: High-volume production versus custom fabrication have different efficiency and flexibility requirements

Budget considerations: Higher-end CNC equipment costs more but offers increased functionality and automation

Every fabrication shop is unique. DINOSAW's expert team has helped hundreds of stone fabricators select the most suitable equipment. Contact us for personalized recommendations to avoid long-term losses from improper selection.

How does DINOSAW handle bridge saw installation and operator training?

We understand that advanced equipment only delivers value when properly used. DINOSAW provides comprehensive "turnkey" service:

Professional technicians perform on-site installation and commissioning after equipment delivery

2-3 days of operational training covering basic operation, daily maintenance, and troubleshooting

Multilingual operation manuals, video tutorials, and technical documentation

Remote support systems for online diagnostics and software issue resolution

Transform Your Stone Workshop with Premium CNC Saw Machine - Elevate Precision & Productivity

Every DINOSAW bridge saw for sale is designed to enhance your competitive advantage. We don't just provide stone CNC machines—we transfer successful experience, helping you achieve improved production efficiency, reduced waste rates, and product innovation.

Custom Solutions: Analyze your actual needs and budget to avoid overinvestment or insufficient functionality

Complete Support: Beyond selling products, we become your long-term technical advisor and support system

Related Products: Stone Block Cutting Machine

Other Machines or Tools

Other Machines or Tools

Are you looking for more new information machines or tools?

RELATED INDUSTRY MACHINES TO BUILD YOUR PROJECTS

Diamond Wire Saw Cutting Machine | Industry-Leading CNC Manufacturer

Jan 11, 2025

CNC Diamond Wire Saw Machine | #1 Hard Materials Cutting & Stone Profiling Expert

Jan 15, 2025

Diamond Wire Saw Granite Block Cutting Machine for sale

Dec 4, 2024

CNC Vertical Wire Saw Machine for High-Precision Cutting

Dec 8, 2024

RELATED INDUSTRY MACHINES TO BUILD YOUR PROJECTS

Diamond Wire Saw Cutting Machine | Industry-Leading CNC Manufacturer

Jan 11, 2025

CNC Diamond Wire Saw Machine | #1 Hard Materials Cutting & Stone Profiling Expert

Jan 15, 2025

Diamond Wire Saw Granite Block Cutting Machine for sale

Dec 4, 2024

CNC Vertical Wire Saw Machine for High-Precision Cutting

Dec 8, 2024

RELATED INDUSTRY MACHINES TO BUILD YOUR PROJECTS

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment