Open Hours:8:30am-20:30pm

Whatsapp:+86 198-5901-3937

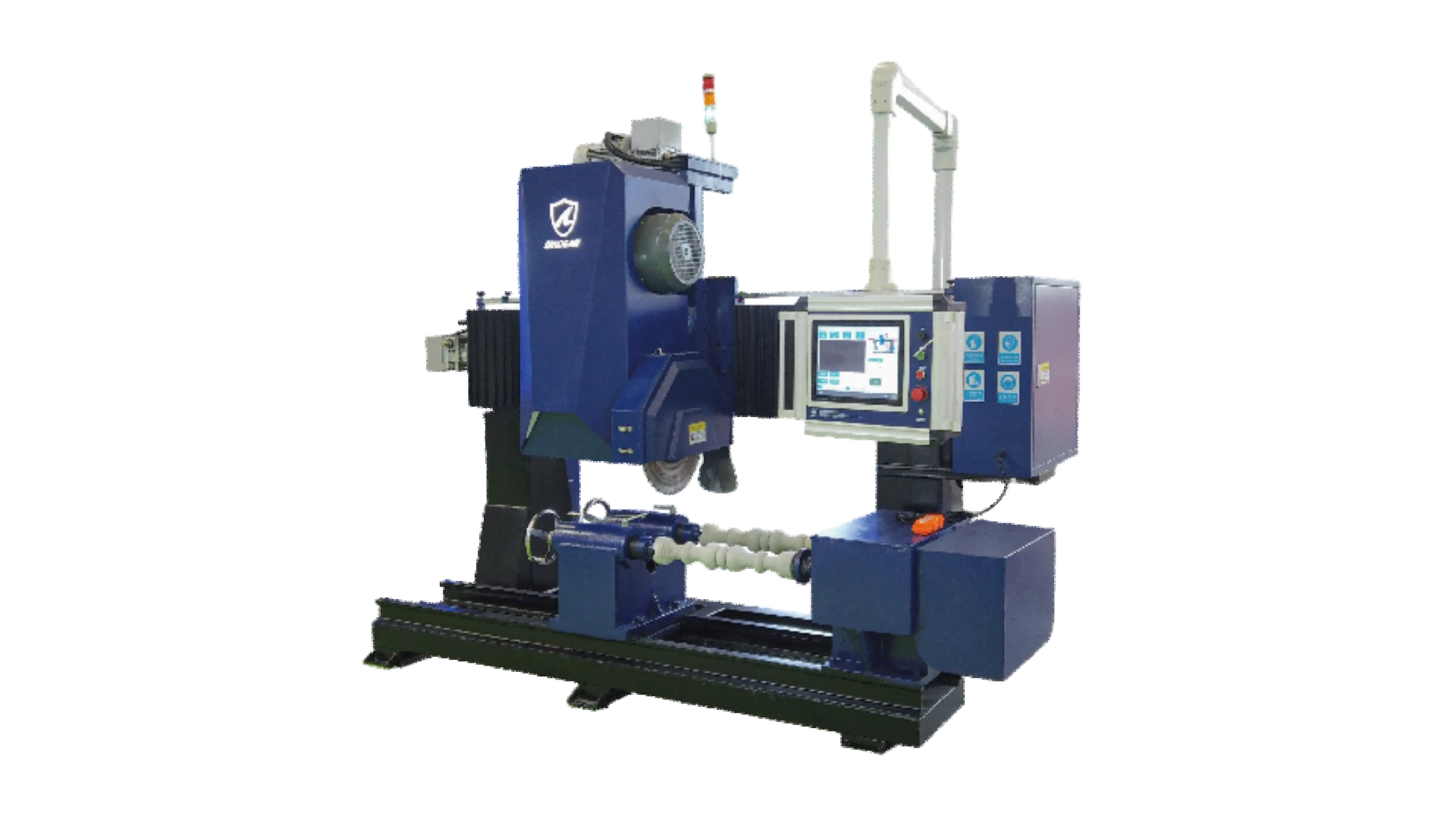

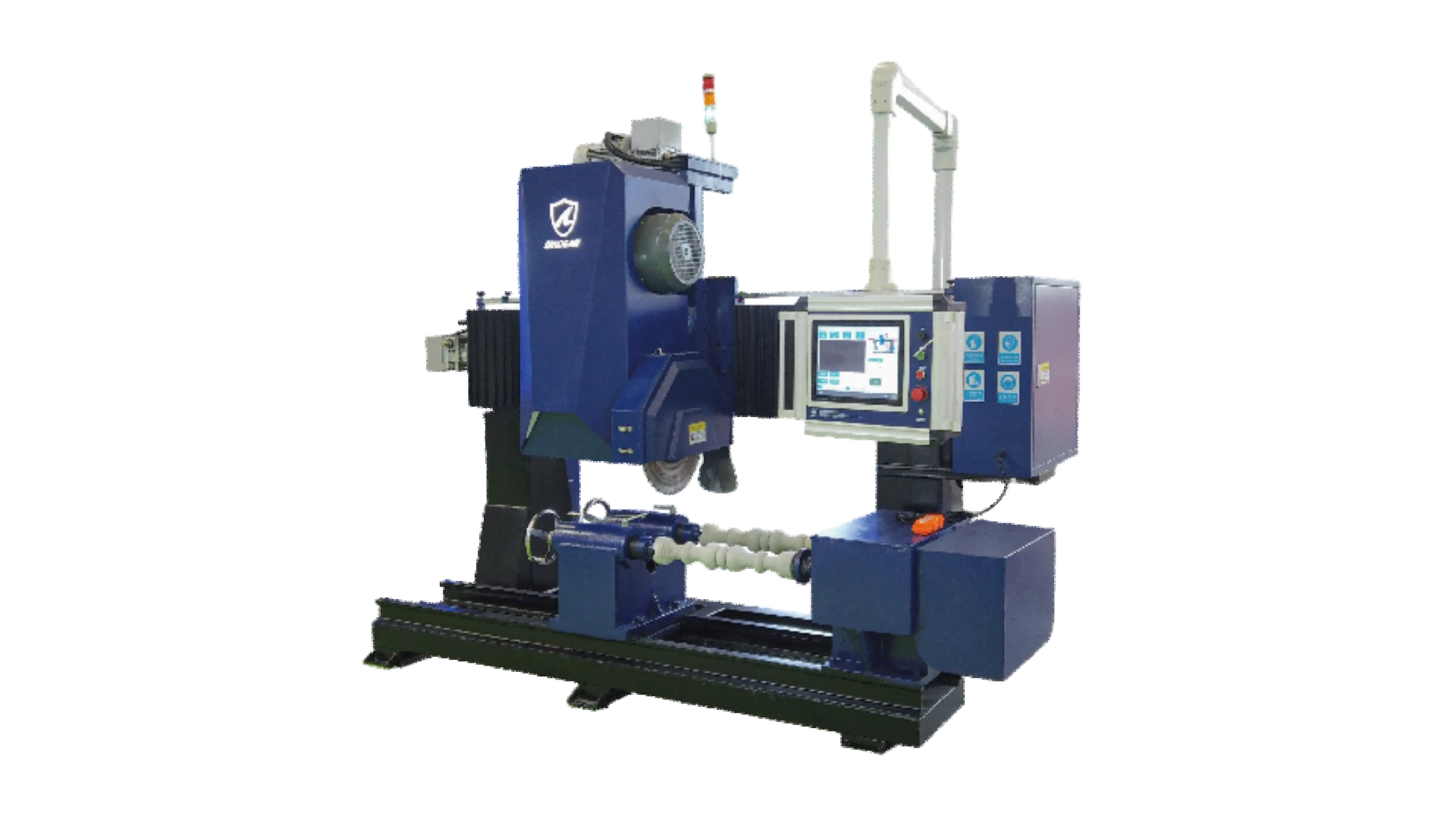

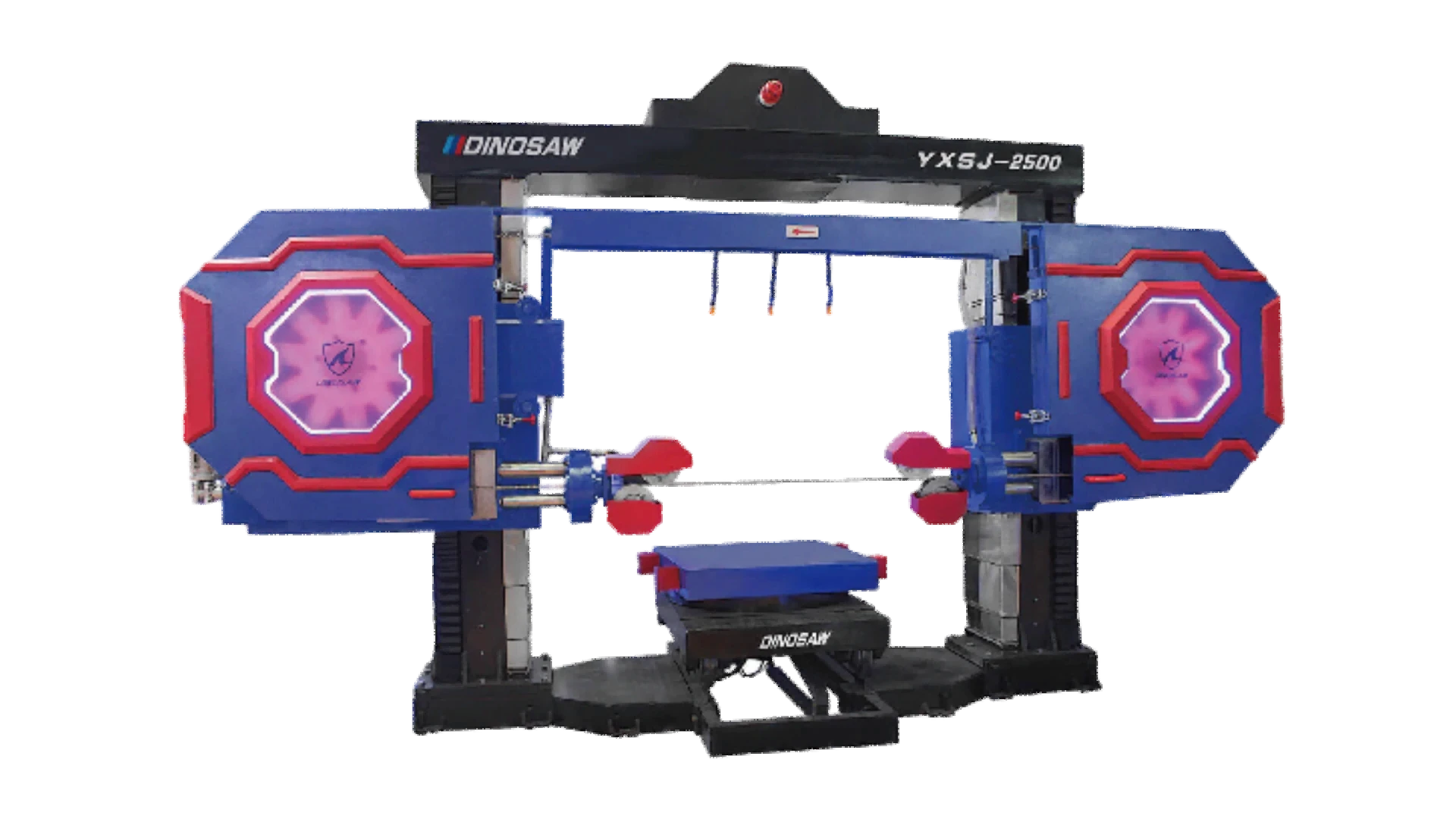

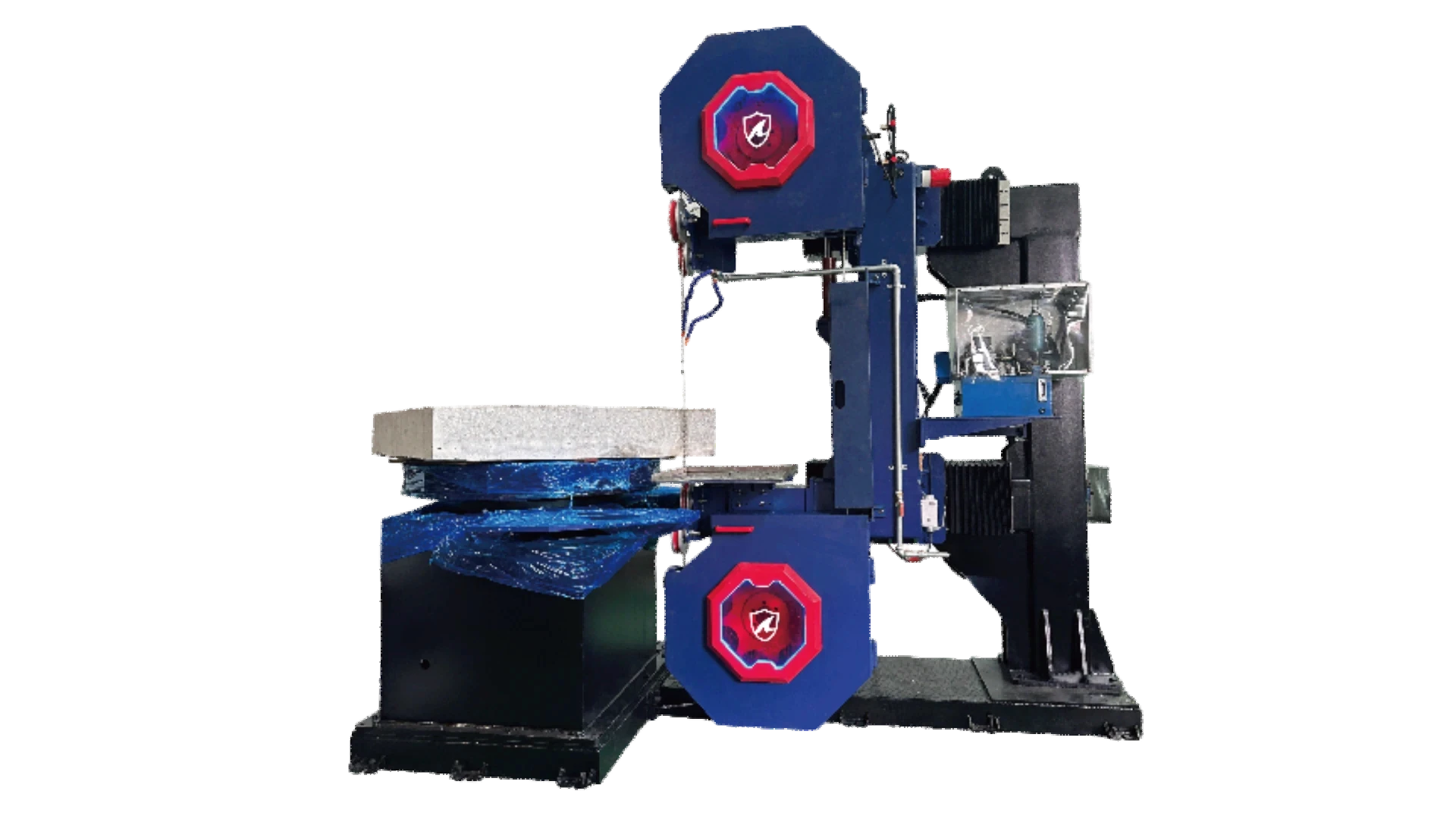

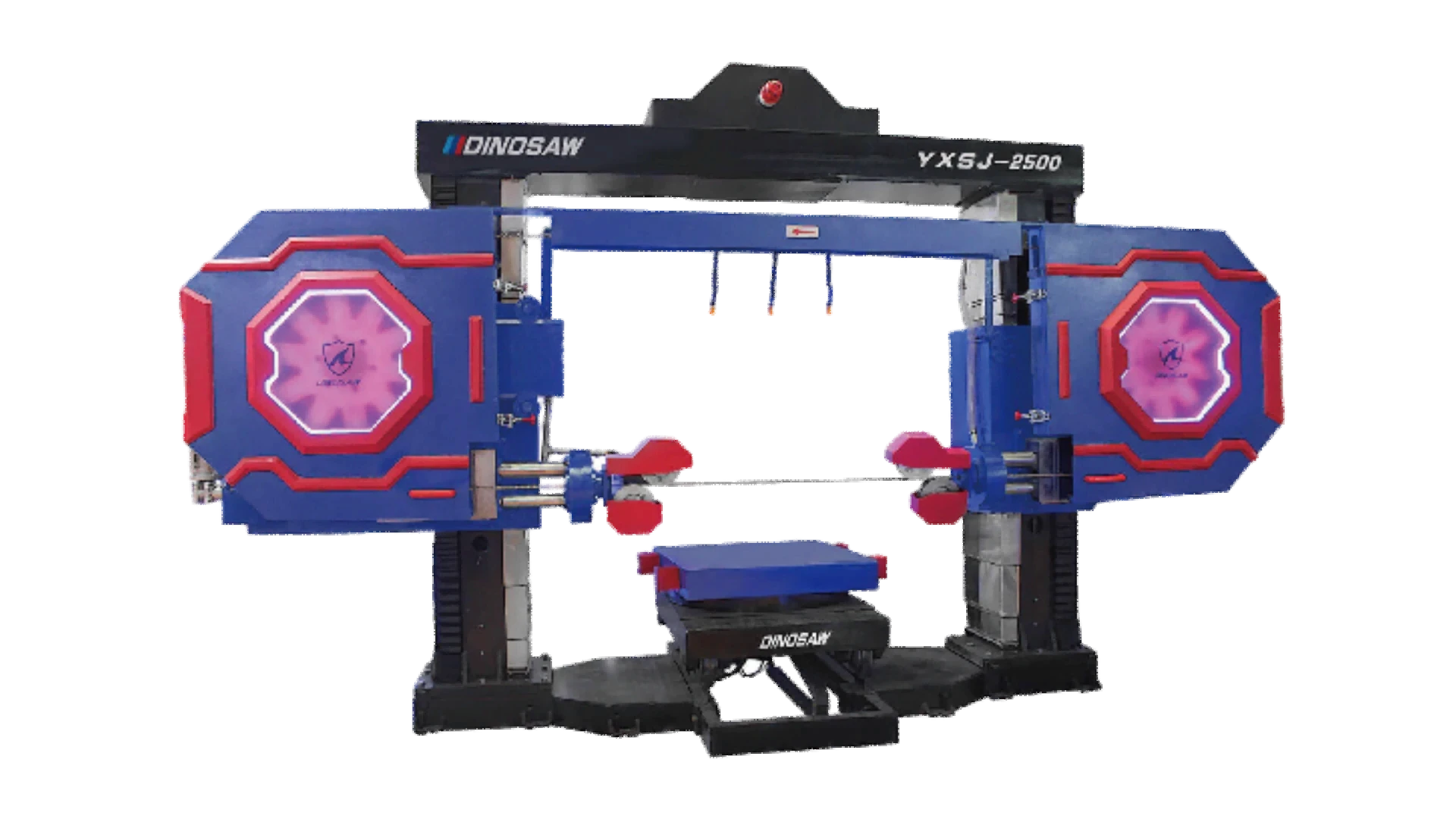

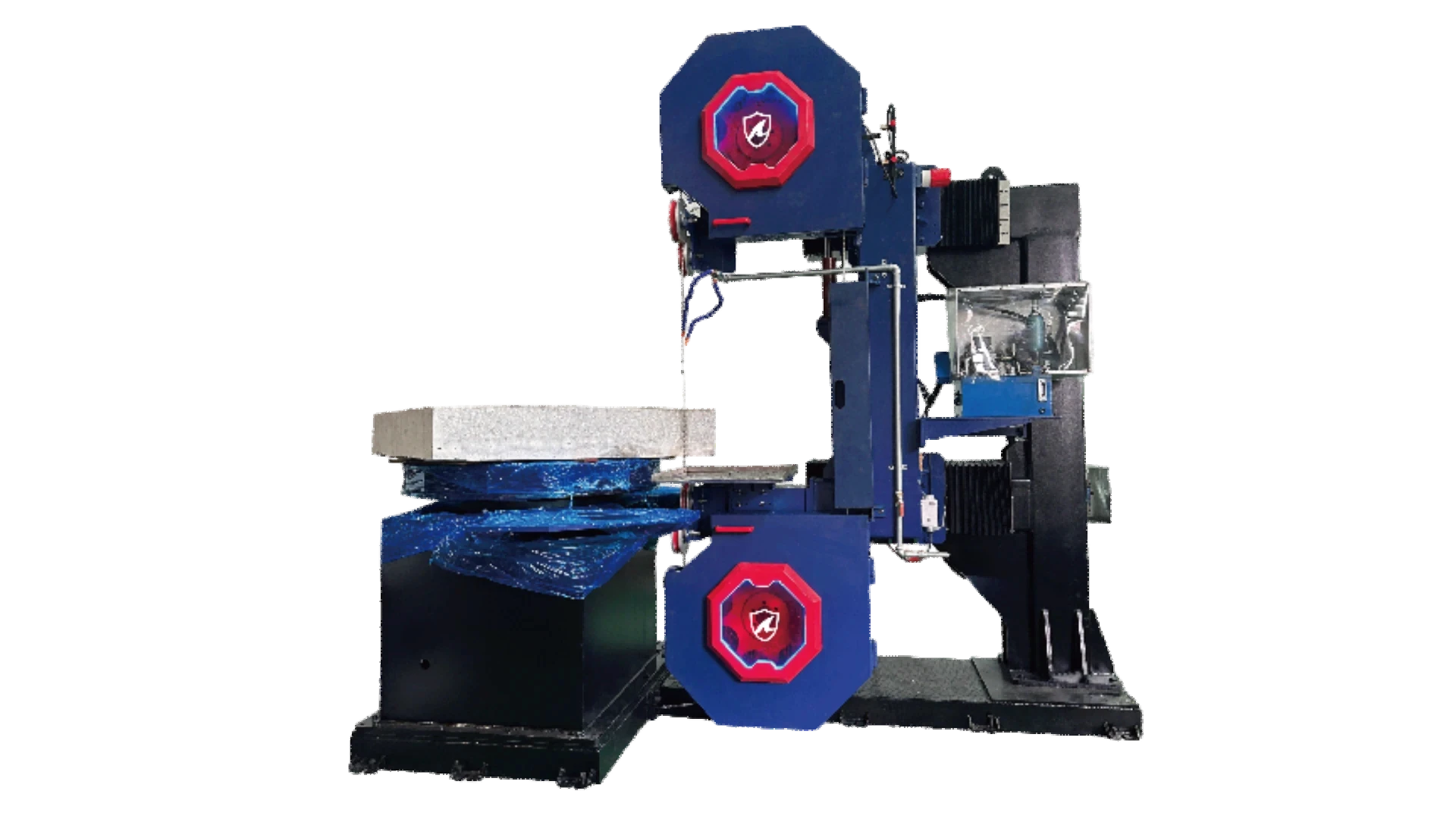

CNC Stone Lathe Machine for Balustrades and Vases

CNC Stone Lathe Machine for Balustrades and Vases

LGFX-600

LGFX-600

DINOSAW CNC stone lathe for stone turning. Ideal for granite balustrades, columns, and vases. CE-certified with automatic tool compensation. Get it today.

DINOSAW CNC stone lathe for stone turning. Ideal for granite balustrades, columns, and vases. CE-certified with automatic tool compensation. Get it today.

DINOSAW CNC stone lathe for stone turning. Ideal for granite balustrades, columns, and vases. CE-certified with automatic tool compensation. Get it today.

Share

Machine Details

Addressing Key Challenges in Stone Lathe Operations

Key Pain Points of Stone Cutting

Insufficient Profiling Accuracy

Traditional equipment struggles with ±1mm errors in ancient Egyptian-style carved balustrades, leading to 20%+ scrap rates in premium stone.

Inefficient Material Switching

Manual parameter adjustments between granite and marble cause more daily downtime.

Over-Reliance on Skilled Labor

Complex curved surface programming requires hours per project and specialized technicians.

Production Bottlenecks

Multi-step processing for ancient stone urns extends lead times by 50%.

DINOSAW's Core Value Proposition

Smart Multi-Material Compatibility

Adaptive spindle automatically adjusts parameters for black granite, marble, and engineered stone, boosting efficiency.

Zero-Programming Production

Direct CAD import (.dwg/.step) reduces programming time for stone railing carvings.

Single-Pass Forming Technology

Integrated cutting + polishing on a lathe without secondary polishing.

Technology & Competitive Advantages

Technical Specs

Operational Efficiency Gains

Tool Life Extension: Diamond blade lifespan increased via wear prediction

Energy Savings: Lower kWh consumption for stone turning lathe

Labor Reduction: 1 operator manages 3+ machines simultaneously

Select the Best Stone Lathe manufacturer:DINOSAW

Precision Revolution: ±0.5mm Accuracy Eliminates 20% Scrap Rates

DINOSAW's intelligent CNC control system achieves ±0.5mm accuracy for intricate carvings like ancient Egyptian-style balustrades, slashing scrap rates from 20%+ to <3%. Real-time wear compensation ensures flawless curved surfaces for vase capitals and columns.

Smart Material Switching: Granite-to-Marble Changeovers in 10 Minutes

Our adaptive spindle technology seamlessly handles granite, marble, and engineered stone. With 150+ preset material profiles auto-adjusting cutting speed, torque and cooling parameters, daily downtime drops by 80%.

Zero-Programming Production: CAD-to-Finished Product

Directly import .dwg/.step files – AI algorithms auto-generate toolpaths, reducing programming time for Roman column cutting from 8 hours to 5 minutes. G-code optimization eliminates redundant tool movements.

Single-Pass Forming: Cut + Polish in One Operation

Integrated diamond cutters with optional polishing setting achieve smooth finishes on heritage balustrades, eliminating secondary polishing and halving production cycles.

Global Competitiveness: Slash Energy & Labor Costs

Energy: Permanent magnet motor plus frequency converter reduces reduces stone turning energy by 40%.

Labor: 1 operator manages 3+ machines simultaneously (-70% labor costs)

Applications & Case Studies: From Royal Balustrades to Artistic Vases

Heritage Restoration:Temple Balustrade Replication

Challenge: 340 travertine balusters

Solution: 3D scan reverse engineering + batch processing

Result: 4-month completion with 98.7% historical pattern accuracy

Luxury Villa Columns: Neoclassical Marble Production Line

Configuration: LGFX-600 quad-spindle lathe (40 Corinthian capitals/day)

Tech Highlights:

≤0.3mm error on column fluting

±0.1mm auto-compensation

Artistic Stone Vases: Dynamic Curved Surfaces

Innovations:

Ultra-thin walls: 3mm minimum thickness stability

Asymmetric curves: B-spline interpolation achieves 0.01° angular precision

Municipal Projects: Granite Railing Standardization

Quanzhou Case Study:

Output: 1,200 linear meters/day of balustrades

Material utilization: Improved from 68% to 92%

Conclusion & CTA: Lead the Smart Stoneworking Era

Industry Validation:

Global stone machinery market grows at 4.7% CAGR (2023-2030), with smart equipment penetration exceeding 65%.

As a Global Stone Tech Brand , DINOSAW drives innovation with 3-month softwre upgrade and 12-month hardware upgrade cycles.

DINOSAW Offers:

✅ Customized stone turning lathe for sale

✅ Sample processing solutions

✅ Assorted diamond tools

✅ 12-month warranty + 4-hour global response

Take Action Now!📞 Call +86-19859013937/Whatsapp to get your stone lathe machine

Machine Details

Addressing Key Challenges in Stone Lathe Operations

Key Pain Points of Stone Cutting

Insufficient Profiling Accuracy

Traditional equipment struggles with ±1mm errors in ancient Egyptian-style carved balustrades, leading to 20%+ scrap rates in premium stone.

Inefficient Material Switching

Manual parameter adjustments between granite and marble cause more daily downtime.

Over-Reliance on Skilled Labor

Complex curved surface programming requires hours per project and specialized technicians.

Production Bottlenecks

Multi-step processing for ancient stone urns extends lead times by 50%.

DINOSAW's Core Value Proposition

Smart Multi-Material Compatibility

Adaptive spindle automatically adjusts parameters for black granite, marble, and engineered stone, boosting efficiency.

Zero-Programming Production

Direct CAD import (.dwg/.step) reduces programming time for stone railing carvings.

Single-Pass Forming Technology

Integrated cutting + polishing on a lathe without secondary polishing.

Technology & Competitive Advantages

Technical Specs

Operational Efficiency Gains

Tool Life Extension: Diamond blade lifespan increased via wear prediction

Energy Savings: Lower kWh consumption for stone turning lathe

Labor Reduction: 1 operator manages 3+ machines simultaneously

Select the Best Stone Lathe manufacturer:DINOSAW

Precision Revolution: ±0.5mm Accuracy Eliminates 20% Scrap Rates

DINOSAW's intelligent CNC control system achieves ±0.5mm accuracy for intricate carvings like ancient Egyptian-style balustrades, slashing scrap rates from 20%+ to <3%. Real-time wear compensation ensures flawless curved surfaces for vase capitals and columns.

Smart Material Switching: Granite-to-Marble Changeovers in 10 Minutes

Our adaptive spindle technology seamlessly handles granite, marble, and engineered stone. With 150+ preset material profiles auto-adjusting cutting speed, torque and cooling parameters, daily downtime drops by 80%.

Zero-Programming Production: CAD-to-Finished Product

Directly import .dwg/.step files – AI algorithms auto-generate toolpaths, reducing programming time for Roman column cutting from 8 hours to 5 minutes. G-code optimization eliminates redundant tool movements.

Single-Pass Forming: Cut + Polish in One Operation

Integrated diamond cutters with optional polishing setting achieve smooth finishes on heritage balustrades, eliminating secondary polishing and halving production cycles.

Global Competitiveness: Slash Energy & Labor Costs

Energy: Permanent magnet motor plus frequency converter reduces reduces stone turning energy by 40%.

Labor: 1 operator manages 3+ machines simultaneously (-70% labor costs)

Applications & Case Studies: From Royal Balustrades to Artistic Vases

Heritage Restoration:Temple Balustrade Replication

Challenge: 340 travertine balusters

Solution: 3D scan reverse engineering + batch processing

Result: 4-month completion with 98.7% historical pattern accuracy

Luxury Villa Columns: Neoclassical Marble Production Line

Configuration: LGFX-600 quad-spindle lathe (40 Corinthian capitals/day)

Tech Highlights:

≤0.3mm error on column fluting

±0.1mm auto-compensation

Artistic Stone Vases: Dynamic Curved Surfaces

Innovations:

Ultra-thin walls: 3mm minimum thickness stability

Asymmetric curves: B-spline interpolation achieves 0.01° angular precision

Municipal Projects: Granite Railing Standardization

Quanzhou Case Study:

Output: 1,200 linear meters/day of balustrades

Material utilization: Improved from 68% to 92%

Conclusion & CTA: Lead the Smart Stoneworking Era

Industry Validation:

Global stone machinery market grows at 4.7% CAGR (2023-2030), with smart equipment penetration exceeding 65%.

As a Global Stone Tech Brand , DINOSAW drives innovation with 3-month softwre upgrade and 12-month hardware upgrade cycles.

DINOSAW Offers:

✅ Customized stone turning lathe for sale

✅ Sample processing solutions

✅ Assorted diamond tools

✅ 12-month warranty + 4-hour global response

Take Action Now!📞 Call +86-19859013937/Whatsapp to get your stone lathe machine

Other Machines or Tools

Other Machines or Tools

Are you looking for more new information machines or tools?

RELATED INDUSTRY MACHINES TO BUILD YOUR PROJECTS

Diamond Wire Saw Cutting Machine | Industry-Leading CNC Manufacturer

Jan 11, 2025

CNC Diamond Wire Saw Machine | #1 Hard Materials Cutting & Stone Profiling Expert

Jan 15, 2025

Diamond Wire Saw Granite Block Cutting Machine for sale

Dec 4, 2024

CNC Vertical Wire Saw Machine for High-Precision Cutting

Dec 8, 2024

RELATED INDUSTRY MACHINES TO BUILD YOUR PROJECTS

Diamond Wire Saw Cutting Machine | Industry-Leading CNC Manufacturer

Jan 11, 2025

CNC Diamond Wire Saw Machine | #1 Hard Materials Cutting & Stone Profiling Expert

Jan 15, 2025

Diamond Wire Saw Granite Block Cutting Machine for sale

Dec 4, 2024

CNC Vertical Wire Saw Machine for High-Precision Cutting

Dec 8, 2024

RELATED INDUSTRY MACHINES TO BUILD YOUR PROJECTS

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment

CONTINUOUSLY IMPROVE PRODUCTIVITY FOR USER

Customer first | Teamwork | Embrace change | Integrity | Passion | Commitment